MATERIAL-HANDLING SYSTEMS:STORAGE SYSTEMS

STORAGE SYSTEMS

Various types of racks have been developed to store loads of different sizes and shapes. One of the simplest storage systems is block stacking, where loads (which may or may not be palletized) are simply stacked on top each other with no separate support structure. While block stacking is inexpensive and provides dense storage (i.e., little or no space is lost due to air between the loads), its use is limited in practice because only certain types of loads (such as appliances or furniture packed properly in cartons) can be stacked without crushing / damaging the loads at the bottom and access to individual loads (i.e., load selectivity) is very limited. In fact, loads must be removed from a stack, starting with the load at the top. This leads to last-in-first-out (LIFO) stock rotation, which is not desirable for many storage systems.

A fundamental trade-off that exists in storage systems design is that between storage density (how well the cubic volume is utilized) and load selectivity (how easily and how fast one can store or retrieve each load). Loss in storage density often occurs due to aisles and due to space created between individual loads when they are palletized and / or stored in a rack. Generally speaking, higher-density storage systems offer lower selectivity. A well-designed and well-engineered storage system provides the right level of load selectivity while maximizing the storage density. It must also provide the right level of support for the loads and must be compatible with the device / method used for storing and retrieving the loads.

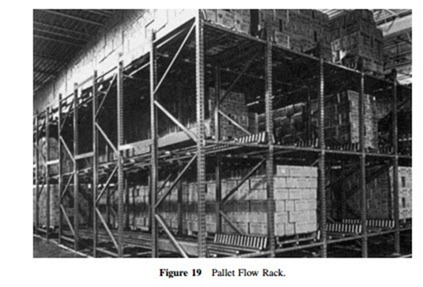

For example, in many storage systems, stock is rotated on a first-in-first-out (FIFO) basis, which implies that random access to every single load in the system may not be necessary. Hence, the right level of selectivity would ensure that, given a set of loads of the same type, only the oldest load needs to be easily accessible. This concept has, in fact, led to pallet flow racks, where loads are stored in lanes and each lane holds multiple loads of the same type. At any given time, only the loads in the front of each lane (which, by definition, are the oldest loads in each lane) are easily accessible. Pallet flow racks increase storage density by minimizing the space required by aisles. However, some space is wasted within each lane because the number of loads in a lane varies over time and, at any given instant, some lanes may be full while others are nearly empty.

Note that block stacking has another advantage: flexibility. Since there is no permanent rack structure, when stacked loads are retrieved (or if the need for storage space decreases over time), the floor space that opens up may be used for other purposes, provided new loads are not stored in the system shortly thereafter. To protect and support the loads at the bottom while avoiding the cost and loss of flexibility associated with a permanent rack, some systems use portable racks, also known as stacking frames, (Figure 17), which are basically self-contained steel units made up of four posts attached to a deck. (An alternative design is a frame that is attached to the pallet itself.)

With portable racks, the weight of each load in the stack is transferred to the floor. It must be noted, however, that portable racks create air between the loads (storage density decreases) and load selectivity is still very limited. Also, portable racks are typically designed for use with palletized loads, and the time to store or retrieve a load may be affected when portable racks are used.

Hence, to maintain convenient and fast load access while providing support for each load in the system, many storage systems use permanent racks. Basic examples of permanent racks include (1) single-deep selective rack (Figure 18), (2) double-deep rack, (3) drive-in or drive-through rack, (4)

pallet flow rack (Figure 19), (5) mobile rack (which slides on permanent tracks installed on the floor), and (6) Cantilever rack (Figure 20), which is suitable for storing bar stock. When equipped with wooden decks, cantilevered racks may also be used for storing furniture.

With an increasing desire to utilize the cube well and the availability of lift trucks that have higher reach, there is a tendency to build taller rack structures, especially in regions where land or floor space is very limited. While high cube utilization and going up instead of going out are appropriate

objectives in many instances, it must also be stressed that taller racks can have higher overall cost. As a result, given two storage systems with equal total storage capacity, the one with a taller rack (and smaller footprint) may be more expensive with respect to the total rack cost. (This must of course be traded off against potential savings created by a smaller footprint.)

Two other factors affect the rack cost and rack height. First, racks are more expensive in regions with high seismic activity since they must meet more stringent requirements. Taller racks in such regions may also present a safety hazard. Second, small deviations in the floor surface are amplified when the forks of the truck are raised to the higher tiers of the rack. Consequently, a wavy floor surface may create serious problems for a narrow-aisle truck serving a tall rack. One must also ensure that the floor loading capacity (psi) is sufficient for the rack being considered. A taller rack requires a higher floor loading capacity. Last but not least, one must also consider fire safety and sprinkler systems when selecting the height and type of rack used in a storage system. Tall racks or decked racks may require modifications or enhancements to the sprinkler system.

Comments

Post a Comment