PLANT AND FACILITIES ENGINEERING WITH WASTE AND ENERGY MANAGEMENT:MANAGING PLANT AND FACILITIES ENGINEERING

4. MANAGING PLANT AND FACILITIES ENGINEERING

4.1. Organization and Management of the Plant or Facilities Engineering Function

The plant engineering organization is shaped by many factors that vary widely among enterprises, including the following:

4.1.1. Strategy for Plant Engineering

First and foremost, be in harmony with the strategic plan of the enterprise. Not all enterprises have the same strategic plan for plant engineering, so the organization must be shaped to support the unique objectives for the specific enterprise. Functions assigned to plant engineering can lead com- panies into businesses the mission statement does not recognize. A plant engineer may, by default, become the manager of such businesses as real estate, vehicle repair, electric generating, telephone, building construction, machine building, and scrap metal. Management should make a conscious decision to get into or stay out of a business depending on corporate objectives, skills availability, funding sources, and volume and type of business. Without the strategic decision, the company may be in unwanted businesses it can neither manage nor run profitably. Many companies assign side businesses to contractors. Despite higher unit prices, this may be more cost effective than running an unfamiliar business.

4.1.2. Size of Operation

In a larger organization where delegation is possible, the plant or facilities engineer performs chiefly managerial functions, such as assigning and reviewing the work of others and communicating with superiors, peers, and subordinates. In a smaller organization, the plant engineer may perform many of the engineering, managing, and implementation steps individually.

4.1.3. Type of Operation

The plant engineering organization must be patterned to achieve the mission and objectives of the operation being served. A large, continuous chemical complex will have different organizational needs than a five-day-per-week automotive parts manufacturer or an office building. In a small, light man- ufacturing plant, the plant engineer often has full responsibility for maintenance, support equipment, and the facility itself, with no subordinate employees. Plant engineers in large plants usually have executive status, but inroads by teams and the level of technology and automation are changing organizational relationships and structures. The degree of automation also has an impact on organi- zation of plant engineering.

4.1.4. Managerial Style and Structure

Until recently, plant engineering organizations were essentially hierarchical, but now team manage- ment techniques are being used increasingly in industries and businesses. This is particularly true when total productive maintenance is used. In this concept, maintenance people who were formerly in a separate department are integrated into manufacturing or operating departments, where they are part of a close-knit team rather than outside. While maintenance and plant engineering people may lose some of their individuality and visibility, the benefits of teams in improving productivity are well documented. One advantage of TPM is that intradepartmental conflicts are avoided and everyone is motivated toward a single goal of maintaining production in the most efficient manner.

Another new paradigm is that plant and facilities engineering operates as a professional-services firm composed of multifunctional teams of experts who provide services to other departments within the organization. Charges against departmental or activity budgets are made for services rendered.

4.1.5. Area of Responsibility

The organization of the plant engineering activity depends on top management’s perception of its responsibilities in relation to other departments. Plant engineering often acquires unwanted or inap- propriate, but necessary, functions that do not fit within other departments. In a TPM situation, traditional reporting relationships of plant engineering personnel may be blurred because individuals may report to operating or administrative departments rather than directly to the plant engineer. The plant engineer is obliged to adopt a new organizational structure and concentrate on communicating with manufacturing or other departments that manage plant engineering people. The plant engineering

function should report to the plant manager, general manager, chief engineer, or assistant plant man- ager. This direct line to key executives can facilitate obtaining the resources necessary to keep the facility operating optimally.

4.1.6. Availability of Qualified Personnel

The availability of qualified personnel relative to operational requirements may force a more prag- matic approach to organization. In highly technical operations, unavailability of qualified people to perform specialized tasks may cause the plant engineer to seek such expertise outside of the orga- nization.

4.1.7. Budgetary Constraints

If upper management views plant and facilities engineering functions as just more overhead, it may be excessively frugal when authorizing budgets. Top managers must realize that plant and facilities engineering are interdependent with production and that adequate funding to perform an optimum job is essential because ‘‘You pay for plant engineering whether you have it or not.’’

Graphical representations of the typical hierarchical organizational structure followed by one of many team configurations are shown in Figure 2 (Lewis and Marron 1973).

4.2. Applying Industrial Engineering Techniques to Plant Engineering Problems

4.2.1. Determining Personnel Requirements

Determining personnel levels is best done by determining the workload for each activity in the plant or facilities engineering department through time study, work sampling, work order estimation, pre- determined times, standard data, video camcorder, or other accepted work measurement technique. Although plant engineering work is often regarded as impossible to measure, there are many repetitive or semirepetitive operations that can be measured with reasonable accuracy. The fact that not all operations can be measured accurately should not deter the plant engineer from obtaining times for those that can be measured.

When the forecast workload becomes available, the plant engineer should compare total hours needed with those available and compute the difference. A workload and backlog report (Figure 4) prepared on any spreadsheet software or by a CMMS and issued monthly to management can help to justify requests for additional employees.

Station jobs (such as boiler operator), which involve continuous attendance vs. jobs where the workload varies according to assignment or demand for service, should be measured according to the actual work content in the operation. If other work can be done on a station job without sacrificing the primary mission, productivity of the operation can be improved.

Factors affecting personnel requirements include type of industry, size and age of the plant, degree of automation, equipment complexity, amount of capital work, level of preventive maintenance, qual- ity requirements, degree of excellence expected and the qualification, availability of labor, and training level of the existing workforce (Palko 1989). Difficulty in finding qualified people to fill plant en- gineering and maintenance jobs motivates some companies to invest in retraining to improve em- ployee competence.

Because plant engineering and maintenance labor cost are visible, these functions are frequent targets of cost cutters. Invisible to top management and buried in overhead or other categories are

costs of excessive downtime, obsolete equipment, utility outages, poorly maintained machines, or other causes of low productivity. Identifying such problems using activity-based costing or value stream analysis allows adequate staffing for plant engineering activities to be justified.

4.2.2. Decision Making and Problem Solving / Data Analysis

As a manager of a significant part of the operation, the plant engineer must be an effective decision maker and problem solver. Unlike the manager of a production operation, the plant engineer is typically faced with new challenges, unusual problems, and nonrecurring decisions almost every minute of every day. Solutions and decisions must be made quickly and accurately for the benefit of the organization. The decision-making and problem-solving process is as follows:

1. Identify the problem, not symptoms—use statistics to find the real problem.

2. Collect all available causes and other data—make fishbone diagrams.

3. Analyze data—develop creative ideas.

4. Select and test alternatives.

5. Pick the best solution—test and implement the solution.

Seldom does a hands-on plant engineer have the luxury of time to implement the formalized approach. Using the above thought process coupled with other industrial engineering knowledge, the plant engineer can intuitively and informally develop solutions to many diverse problems instanta- neously. While the above basic method for problem solving is valid, familiarity with kaizen, Ishikawa, 8D, 5 why, brainstorming, decision tree, and other solution-generation methods is advantageous.

4.2.3. Benchmarking Plant Engineering

A plant engineer who wants an organization on the cutting edge of technology should consider benchmarking the organization against others in comparable fields. The benchmarking process in- volves sharing information with other companies and emulating best practices in critical areas (Gulati and Lach 1997; Raymond 1993).

4.2.4. Productivity and Quality in Plant Engineering

Plant engineering in both manufacturing and service facilities and operations use the same resource inputs of capital, equipment, humans, materials, and energy, but outputs can be quite different. The outputs of manufacturing are chiefly discrete products measured in pieces, tons, gallons, dollars, or other similar measures. Measures of output in a service facility may be in industry-specific terms such as meals served, patients treated, students enrolled, cars parked, nights occupied, or the dollar value thereof.

The use of industrial engineering techniques in plant engineering can be the key to improvement of productivity. Work measurement, work sampling, computerized maintenance management, equip- ment down time analysis, predictive maintenance, proper layout, effective floor utilization, and ef- fective strategy planning for facility utilization all tend to improve productivity of resources. Due to the close relationship between maintenance and plant engineering, the following productivity mea- sures for maintenance can be applied or modified to measure plant engineering effectiveness:

Accidents avoided / accident rate Energy losses eliminated Material costs reduced

The use of productivity formulas is limited only by the imagination of the user. Formulas must be relevant, meaningful to the user, and motivate positive action and continuous improvement in productivity (APC 1981; Steele 1997).

The success of the plant engineering function must be measured not only in quantity but also in quality of work produced and quality of the organization. There are many assessment tools for quality that address plant engineering. If the organization is competing for the Malcolm Baldrige Award, Shingo Prize, North American Maintenance Excellence, or other awards of excellence, going through the process will motivate maintenance and plant engineering to improve performance. Assessment tools such as Tompkins Associates’ Maintenance Scoreboard can highlight gaps that when remedied can lead to significant improvements.

4.2.5. Work Measurement Techniques in Plant Engineering

Although there is a widely held perception that maintenance and plant engineering work is not measurable, there have been many successful applications of work measurement to these functions. A number of consulting firms offer maintenance standards, based on MTM or other predetermined time systems, that can be applied to maintenance and plant engineering work. Measurement of plant engineering activities uses a combination of work sampling, time study, and time recording. These times can be used to determine the level of effort and the number of the people required to perform plant engineering tasks.

In some instances, maintenance standards have been developed from extensive time study and converted to standard data, which are then applied to specific jobs being performed by mechanics. The actual time taken by the mechanic is then compared to the computed standard based on work content and the percentage is used to calculate a day work or incentive efficiency. Station jobs such as boiler operators may use a simple reporting system which indicates that assigned work is being done. See Chapter 54 for more information on work measurement.

4.3. Financial Aspects of Plant and Facility Management

4.3.1. Plant Engineering as a Profit Center

Most plant engineering, maintenance, and facilities engineering activities have been viewed by ac- countants and management as expense items or cost centers. Only recently has the concept of viewing these entities as profit centers been promulgated. While this may seem like a minor change, it can add to the profitability of the enterprise through reducing or controlling cost of the facility. Plant engineering and maintenance activities are viewed in some circles as value-added components of the value stream. By applying preventive and predictive maintenance and effective plant engineering practices, plant engineering departments can increase availability of the facility and equipment, thus adding real value to the organization.

4.3.2. Budgeting

Plant engineers are required to submit budgets for materials, suppliers, labor, and capital investment. The budget is a list of proposed sources of income and expected expenditures. When approved, the budget may be viewed as a bank account against which charges can be made. In some cases, de- partments are charged as a professional service, and it is possible for plant engineering to earn a surplus.

Many organizations still use the analysis-of-variance method to determine whether cost objectives are being met within budgeted amounts. This approach gives some indication of actual vs. planned expenditures, but because data are released months after actual events occur, it is difficult to trace how activities could have been performed better.

Activity-based budgeting is ideal for tracking plant engineering functions. Identifying activities actually performed along with the cost drivers allows real-time information to be generated and problem areas identified quickly. Cost distributions between plant engineering and other departments can be done more equitably, and non-value-added activity can be spotted more easily.

4.3.3. Costing

As noted in the section on budgeting, it is incumbent on plant engineers, like all managers, to maintain close control of costs, and make decisions based on accurate cost data. While other chapters in this Handbook detail costing systems, and other cost issues have been noted elsewhere in this chapter, a plant engineer should utilize activity-based costing data to identify non-value-added activity, both within the plant engineering function and throughout the organization. Plant engineers are often blamed for breakdowns, power outages, and other situations that produce non-value-added activity. Elsewhere in this chapter it is noted that a well-run plant engineering function adds value and can enhance profitability for the organization. Activity-based costing is one of the best methods available for collecting cost data and assigning responsibility to the appropriate entity. To implement activity- based costing for plant engineering, the principles are the same as for any other part of the organi- zation, but data from the computerized maintenance management system may be more readily available than in other departments.

4.3.4. Cost Control and Reduction

Plant engineering can add dramatically to the profitability of the company by controlling and reducing costs. A well-run plant engineering organization should establish an annual cost-reduction objective and measure itself against actual achievement. Although careful planning and execution of plant engineering activities can lead to cost reduction and control, the following are specific initiatives plant engineers can take to reduce costs:

1. Ensure cost-effective building designs that have:

(a) Minimum enclosing ratio (wall area / floor area)

(b) Minimum partitions

(c) Efficient heating and air conditioning

(d) Best utilization of the site (possibly through multiple floors)

(e) Low maintenance costs

(f) Standard components

(g) Lowest-cost material to fulfill function and aesthetics

2. Prepare accurate cost estimates of all construction and repair work.

3. Obtain competitive bids from qualified / reliable contractors.

4. Control construction and repair costs to avoid overruns.

5. Avoid engineering change orders with contractors to control costs.

6. Conduct work sampling studies on plant engineering personnel to solve problems and improve efficiency.

7. Apply methods improvement / work simplification techniques to plant engineering operations.

8. Assist other departments in building equipment jigs, fixtures for cost-improvement projects.

9. Practice effective maintenance management using computerized maintenance management systems if appropriate.

10. Provide optimum machine maintenance to improve productivity and avoid downtime.

11. Train and retrain plant engineering personnel to perform efficiently.

12. Apply incentives to plant engineering activities to motivate higher levels of performance.

13. Motivate plant engineering personnel to improve attitudes and reduce absenteeism and labor turnover.

14. Provide a safe workplace for all employees.

15. Involve plant engineering personnel in teams, problem-solving groups, or other participative groups to solve plant engineering problems. Implement total productive maintenance princi- ples throughout the department

16. Reduce parts and stores inventory.

17. Conduct value engineering studies on repair parts or supply items.

Use activity-based costing to identify and eliminate non-value-added activity.

18. Use good environmental practices to reduce or recycle solid waste.

19. Apply productivity and quality measures to plant engineering work.

20. Reduce machine setup time through careful planning.

21. Justify capital expenditures on strategic and competitive bases, not solely on discounted cash flow or hurdle rates.

22. Ensure employee comfort through environmental controls and good ergonomic design.

23. Take energy audits and control demand and power factor charges.

24. Automate energy, heating and cooling, security, and related items using computerized building automation systems.

25. Contract out expensive, undesirable, or hazardous operations.

26. Use the most modern maintenance techniques available.

4.4. Conducting a Facility Survey

When a plant engineer assumes responsibility for an existing facility, it is advisable to conduct a facility assessment to determine the condition and appropriateness of the major facility systems and components. The objective is to develop a plan for correcting, upgrading, or retrofitting these systems. The survey requires preparation, observation, analysis, planning, and action.

4.4.1. How to Conduct a Facility Survey (Piper 1988a)

1. Obtain drawings of facility and find location of critical components.

2. Peruse records of all systems, components, and equipment—repair history, material, specifi- cations, purchase date, age of component.

3. Cite potential trouble spots.

4. Assemble a team of specialists to survey the facility.

5. Prepare an itinerary and schedule for touring the facility.

6. Develop or use a prepared checklist to avoid missing key items.

7. Take a tour or a series of tours, focusing on one or more components during each tour, noting observed conditions.

8. Review corporate strategy to ascertain future use of the facility.

9. Discuss condition of the facility with other engineering and operations personnel, building occupants, or anyone who can provide insight into the condition of the facility or equipment.

10. Generate a report with lists of problems and deficiencies plus recommended corrective actions.

11. Prioritize the lists by classifying problems as critical, serious, routine, or minor.

12. Make cost estimates of required repairs as a part of the report.

13. Issue work orders to have critical and serious problems corrected immediately or within a short time.

14. Schedule other repairs or problem correction as funds and manpower become available.

15. Repeat the survey every three to six months to determine further deterioration or level of correction from previous survey; take further corrective action as required.

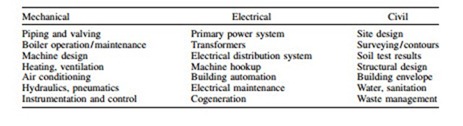

An assessment survey would include a thorough review of the facility systems and components shown in Figure 5. Using the above approach, the new plant or facilities engineer can gain control of assigned responsibilities and develop a plan for resolving identified problems as soon as possible after assuming the new duties.

Comments

Post a Comment