ALIGNING TECHNOLOGICAL AND ORGANIZATIONAL CHANGE:WHAT ARE THE STUMBLING BLOCKS TO ALIGNMENT?

WHAT ARE THE STUMBLING BLOCKS TO ALIGNMENT?

If the benefits of aligning technology and organizational design are so clear, why isn’t it done? We suggest that there are many reasons.

The Future of Technology Is Probabilistic

The technology S curve has been historically documented as describing technology change over the years (Twiss 1980; Martino 1983). The curve, plotted as the rate of change of a performance param- eter (such as horsepower or lumens per watt) over time, has been found to consist of three periods: an early period of new invention, a middle period of technology improvement, and a late period of technology maturity. The technology S curve, however, is merely descriptive of past technology changes. While it can be used for an intelligent guess at the rate of technology change in the future, technology change is sufficiently unpredictable that it cannot be used to predict precisely when and how future change may occur. Fluctuating market demand and / or novelty in the technology base exacerbate the challenge. For example, at Intel, typically at least one third of new process equipment has never been previously used (Iansiti 1999). This probabilistic nature of the technology makes creating aligned technology and organizational solutions difficult because it cannot be known with any certainty what the future organizational-technology solution is likely to be over the long term.

In his study of six information technology project failures, Flowers (1997) concluded that the unpredictability of the technology is a primary complexity factor that contributes to project failure. The more that the technology is at the ‘‘bleeding’’ edge, the greater the complexity. Avoiding over- commitment to any one technology or organizational solution, avoiding escalationary behavior where more resources are thrown at the solution-generation process without adequate checks and balances, and maintaining project-reporting discipline in the face of uncertainty are suggested ways of man- aging the inherent probabilistic nature of technology.

Some Factors Are Less Malleable Than Others

A series of research studies on the process by which technologies and organizations are adapted when technologies are implemented into an organization have shown that adaptations of both tech- nologies and the organization can occur (Barley 1986; Contractor and Eisenberg 1990; Orlikowski and Robey 1991; Orlikowski 1992; Giddens 1994; Rice 1994; Orlikowski et al. 1995; Rice and Gattiker 1999). However, in reality, some adaptations are less likely to occur because some of these factors tend to be less malleable (Barley 1986; Johnson and Rice 1987; Poole and DeSanctis 1990; Orlikowski 1992; DeSanctis and Poole 1994; Orlikowski and Yates 1994). One of these factors is the existing organizational structure. For example, Barley (1986) found evidence that one factor that tends to be less malleable is the existing power structure in the organization. Barley found that when a medical radiation device was installed into two separate hospitals, the work changed in accordance with the organizational structure, not vice versa. That is, in the hospital where the radiologists had more power in the organizational structure than the technicians, the rift between the two jobs became greater with the new technology. In contrast, in the hospital where technicians and radiologists were not separated hierarchically, the technology was used to share knowledge between the two. Another factor often found to be less malleable is what DeSanctis and Poole (1994) refer to as the ‘‘technology spirit,’’ which they define as the intended uses of the technology by the developer or champion who influenced the developer. If the spirit is intended to displace workers, then this spirit is unlikely to be changed during implementation. Research contradicting this assertion has been conducted recently, however (Majchrzak et al. 2000). Moreover, Tyre and Orlikowski (1994) have found that malleability may be temporal, that is, that technologies and structures can be changed, but only during windows of opportunity that may periodically reopen as the technology is used. In their study, the authors found these windows to include new rethinking about the use of the technology or new needs for the technology that were not originally envisioned. These windows did not stay open for very long; thus, over the long term, some factors may have appeared to be less malleable than others.

In sum, then, a stumbling block to integrating TOP is determining which facets of TOP are malleable to facilitate the alignment; when one facet is not malleable, that puts additional pressure on the remaining facet to conform—a pressure that may not be achievable.

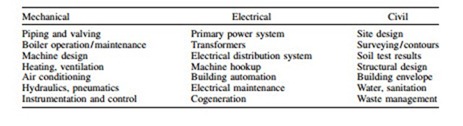

Alignment Requires a Cross-Functional Definition of the Problem For a solution to be sociotechnically aligned, changes may be needed in all aspects of the organi- zation, not just that which is under the purview of the industrial engineer or even the manufacturing manager. Changes may be required in the material-handling organization (which may not report to the manufacturing department), the purchasing department, or the human resources department. For example, Johnson and Kaplan (1987), in their study of just-in-time manufacturing, found that those departments that made changes in the incentive systems (a responsibility outside that of the manu- facturing manager) were less likely to have implementation problems than companies that did not make such changes. This cross-functional nature of aligned solutions creates the problem that because the solution touches on everyone’s responsibilities, it is essentially no one’s responsibility (Whiston 1996). Thus, unless an organizational structure is created to explicitly recognize the cross-functional nature of the alignment, a single function—such as the industrial engineer—cannot create the align- ment. As a result, resolving a cross-functional problem with a single function becomes difficult, if not impossible.

Alignment Is Context Specific and Nonrepeatable

A solution that achieves alignment between technology and organization is typically so context spe- cific that it is not likely to be repeatable in its exact form for the next alignment problem that comes along. This is because of the many factors that must be considered in deriving a technology- organization solution. For example, the global introduction of a new technology product typically now requires some modification in each context in which it is introduced either because of the different needs of customers or different service or manufacturing environments (Iansiti 1999) As another example, altering even one technology factor, such as the degree to which the technology can diagnose its own failures, creates the need to change such organizational factors as the amount of skills that workers must have to operate the technology (Majchrzak 1988). As another example, human supervisory control of automated systems—such as is seen in an oil and gas pipeline control center—involves fault diagnosis, error detection and recovery, and safe handling of rare, critical, and nonroutine events and incidents; these activities require very specific system-dependent sets of skills and teamwork (Meshkati 1996).

This context-specific nature of technology-organization solutions contradicts the desire of many managers today to use ‘‘cookie cutter’’ or repeatable solutions, believing that such solutions will cost less than solutions tailored to each site (Jambekar and Nelson 1996; Kanz and Lam 1996). In addition, Kahneman et al. (1982) have found that the judgments of people in conditions of uncertainty are governed by the availability heuristic (or bias), whereby people judge the likelihood of something happening by how easily they can call other examples of the same thing to mind. If they have no other examples, they will create connections between examples, even though the connections are tenuous. As a result, they will believe that they have a repeatable solution even though one is not warranted.

For example, when globally implementing ERP systems, managers have a choice whether to roll out a single standardized ERP solution worldwide or to allow some issues (such as user interface screens or data structures) to have localized solutions. Forcing a single standardized implementation world-wide has been the preferred strategy in most implementations because it minimizes the com- plexity and resources required to accommodate to localized modifications (Cooke and Peterson 1998). However, implementers at Owens-Corning believe that part of their success in their global ERP implementation was attributable to allowing localized solutions, even though it was slightly more complicated in the beginning. They believe that allowing field locations to tailor some aspects of the ERP system not only ensured the buy-in and commitment of field personnel to the ERP project, but also ensured that the ERP system met each and every field location’s particular needs.

Thus, another stumbling block to alignment is that alignment solutions are best construed as nonrepeatable and highly contextual—a concept that raises management concerns about the resources required to allow such contextualization.

Alignment Requires Comprehensive Solutions That Are Difficult to Identify and Realize A solution aligned for technology and organization is a comprehensive one involving many factors. Today it is widely believed that in addition to strategy and structure, an organization’s culture, technology, and people all have to be compatible. If you introduce change in technology, you should expect to alter your corporate strategy to capitalize on the new capabilities, alter various departmental roles and relations, add personnel with new talents, and attempt to ‘‘manage’’ change in shared beliefs and values needed to facilitate use of the new technology. (Jambekar and Nelson 1996, p. 29.5) Despite this need for integration, Iansiti (1999) charges that ‘‘technology choices are too often made in scattershot and reactive fashion, with technology possibilities chosen for their individual potential rather than from their system-level integration.’’ Iansiti specifically suggests that only when there is a proactive process of technology integration—‘‘one comprising a dedicated, authorized group of people armed with appropriate knowledge, experience, tools, and structure’’—will results be delivered on time, lead times be shorter, resources be adequately utilized, and other performance measures be achieved. In a study of reengineering efforts, Hall et al. (1993) argue that many attempts at reengi- neering have failed because of a focus on too few of the factors needing to be changed. Instead, for reengineering to work, fundamental change is required in at least six elements: roles and responsi- bilities, measurements and incentives, organizational structure, information technology, shared values, and skills.

Thus, another stumbling block to alignment is the need to consider all these factors and their relationships. For many managers and industrial engineers, there are too many factors and relation- ships; as a result, it is far easier to focus mistakenly on only one or a few factors.

Alignment Involves Long Planning Cycles, Where Observable Results and Knowing Whether You Made the Right Decisions Take Awhile Years ago, Lawrence and Lorsch (1967) helped us to recognize the importance of the time horizon of feedback from the environment in determining whether strategic and organizational decisions are the right decisions. In their research, they found that some departments had very quick time horizons, such as a manufacturing department that is structured and oriented to obtaining quick feedback from the environment. In contrast are departments with longer time horizons, such as a research and development department, in which the department is organized to expect feedback about their work over a much longer time period. Lawrence and Lorsch further found that these different time horizons of feedback created different needs for organizational structures, performance-monitoring systems, and personnel policies. The technology-development process can be characterized as one that has a long planning cycle so that the time horizon of feedback may be months or years. For example, the average CIM implementation may take up to 3 years to complete; while the implementation of a large ERP system takes at least 18 months. As a result, managers and engineers need to make decisions about the design of the technology-organization solution in the absence of any data from the field. While some of these decisions may be changed later if data from the field indicate a problem in the design, some of these decisions are changeable only at great cost. This creates a bias toward conservativeness, that is, making decisions that minimize risk. As a result, only those factors that decision makers have historical reason to believe should be changed are likely to be changed, in- creasing the probability of misalignment. Thus, another stumbling block to achieving alignment is the long planning cycle of technology-organizational change, which tends to create a bias against change because learning whether planning decisions are the right ones.

Alignment Involves Compromises

Given the many factors involved in deriving an aligned solution and the many functions affected by an aligned solution, the final aligned solution is unlikely to be an idealized solution. Rather, the final solution is likely to be the outcome of a series of negotiations among the relevant parties. For example, a labor union may not want to give up the career-progression ladder provided by specialized jobs and embrace cross-functional teamwork; management may not want to give up the decision-making control they enjoy and embrace autonomy among the teams. The process of negotiating these different positions to result in some amicable compromise may be difficult and frustrating, adding to the challenges imposed by alignment.

Information technology, because it tends to break down organizational barriers, turfs, and layers, could face opposition from individuals entrenched in the companies’ hierarchy. For example, pro- duction planning, inventory control, and quality control will increasingly be under the control of front-line employees, and this will pose a major threat to low-level supervisors and middle managers (Osterman 1989) and may even lead to their extinction (Drucker 1988).

Comments

Post a Comment