INDUSTRIAL ENGINEERING APPLICATIONS IN HOTELS AND RESTAURANTS:DEVELOPING EFFICIENT WORK ENVIRONMENTS FOR HOTELS AND RESTAURANTS Overview

1. OVERVIEW

In many aspects, the hospitality industry, which includes hotels and restaurants, is just like most other industries. In fact, components such as the kitchen and the laundry can be viewed as small factories. Several aspects, however, distinguish the hospitality industry from other industries. These differences center on the industry’s products. Two of the most important product characteristics are the direct link between production and delivery and the perishable nature of the product (Nebel 1991). Unlike those in many industries, most of the hospitality industry’s products must be consumed when and where they are produced. Therefore, in order to be competitive, hotels and restaurants must be able to produce products efficiently when and where consumers want them. The necessary levels of efficiency can be achieved through the application of industrial engineering techniques and prin- ciples. This chapter covers some of the more important applications that help hotels and restaurants maintain their competitiveness.

2. DEVELOPING EFFICIENT WORK ENVIRONMENTS FOR HOTELS AND RESTAURANTS

Overview

One area in which the application of industrial engineering techniques and principles has become increasingly important is improving worker efficiency. Between 1988 and 1997, the productivity, in output per hour, in food service kitchens decreased at an average annual rate of 0.6% per year (U.S. Bureau of the Census 1999).

Operators have tried many things in their attempts to slow and reverse this trend. Many operations have turned to technology and increased automation as a possible solution. While the incorporation of technology in the kitchen is important, Clark and Kirk (1997) failed to find a positive relationship between implementation of technology and productivity. Operations have also sought to improve productivity by purchasing labor in the form of convenience foods and increasing utilization of self- serve systems (Schechter 1997). Still other operations have sought to improve productivity though kitchen design. A study on trends in kitchen size, found that it has been steadily decreasing (Ghiselli et al. 1998). These smaller kitchens have reduced the distances workers must walk to prepare meals. If workers are walking less, they can become more productive (Liberson 1995). To develop smaller, more efficient kitchens, designers have used a variety of methods. One of the better ones is design by consensus (Avery 1985).

Design by Consensus

Overview

This technique uses the same standard relationship charts and diagrams as recommended for tradi- tional design methods by some of the leading experts on food service layout and design (Almanza et al. 2000; Avery 1985; Kazarian 1989). However, there are major differences between design by consensus and some more traditional design methods. Traditional design methods have centered on management providing operational information to a kitchen design professional. The design profes- sional takes that information and, based on experience and training, develops a layout for the facility. Design by consensus recognizes that workers who will be utilizing the facility have valuable infor- mation that can be used to improve the design. Design by consensus does not eliminate the need for the professional designer. Rather, it provides the designer with additional information that can lead to a more efficient, user-friendly design. Information is collected from workers by the use of rela- tionship charts.

The first step to preparing a relationship chart is to identify all work centers in the facility. Once this has been accomplished, they are entered into a relationship chart as shown in Figure 1. The chart is now ready to distribute to the workers who will be using the facility. Along with the charts, the workers are provided instruction on how to complete the charts. They are instructed to rate the importance of placing each pair of work centers close together. The ratings can be on a seven-point scale, using numbers from zero to six (Kazarian 1989), or a five-point scale, using numbers from zero to four (Almanza et al. 2000; Avery 1985). While the seven-point scale allows for greater differentiation, the five-point scale is easier for nonprofessional designers to use. Because the workers are not professional designers, the five-point scale is often used.

The five-point scale is anchored at ‘‘not important to be located close together’’ (0) and ‘‘very important to be located close together’’ (4). To determine the level of importance, the workers must consider how often they move between the two work centers, the frequency, and other factors such as any load they will be carrying and time limitations to travel the distance between the work centers. Figure 1 shows an example of a completed relationship chart.

Once all workers have completed relationship charts, the charts are consolidated into a single chart. To ensure the lowest possible production costs, the highest-paid employees should engage in as little unproductive action as possible, such as walking between work centers. Therefore, when the charts are consolidated, weights are assigned to the different charts based on who submitted the chart. For example, the ratings of a relatively high-paid chef would be weighted higher than those of a lower-paid worker such as a dishwasher. This will lead to an arrangement that will help maximize the productivity of the highest-paid workers and as a result, lower production costs. Figure 2 shows an example of a consolidated relationship chart.

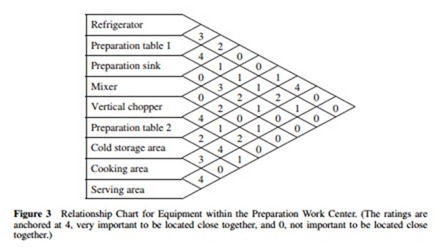

Once the consolidated relationship chart for the work centers has been completed, the designer can develop relationship charts for the equipment within the individual centers. As before, the first step is to determine all equipment that is to be located in the particular work center. The equipment is then listed on the relationship chart just as the work centers were listed on their relationship chart (Kazarian 1989).

While listing only equipment on the chart will help the designer determine the optimum layout for the particular work center, it ignores any relationships between equipment within the work center and other work centers. This is important because it is possible to have an efficient layout within a work center that is not the best layout for the facility. For example, Figure 2 shows that the most important links to the preparation work center are with the cooking work center, followed by the cold storage area and the serving area. If only the equipment is listed on the relationship diagram for the preparation area, then the designer will not know where in the preparation area the movement to the other work centers originates or terminates. Thus, while the layout developed for the preparation area might be the most efficient for that area, the designer has no way of knowing whether it is the optimum layout for the operation. To correct this deficiency, those work centers with the greatest link to the work center for which the relationship chart is being prepared should be included. As shown in Figure 3, the cooking, cold storage, and serving areas have been included in the relationship chart for the preparation area. It is important not to include more than the top two or three linked work centers in the chart. The addition of less important linked work centers to the chart will increase the complexity while adding very little useful information.

Using the information from Figure 3, the designer can easily see that the preparation area should be arranged so that preparation table 2 is located nearest the cooking area and the refrigerator is located nearest the cold storage area. The fact that there are no important links between the serving area and any of the equipment in the preparation area does not mean that the link between the two areas is not important, just that movement between the two areas is likely to be to or from any of the pieces of equipment in the work center.

While the consolidated relationship charts for the work centers within the facility and the equip- ment within the work centers provide valuable information, it is sometimes difficult to visualize the optimum layout in the numbers in the chart. This is particularly true if the relationship chart has a large number of work centers or pieces of equipment listed on it. Therefore, it is helpful to display the information in the form of a relationship diagram that highlights the most important links.

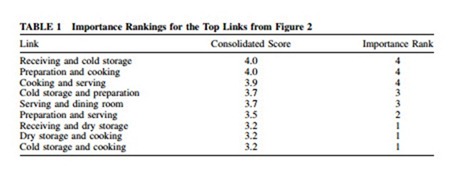

To prepare the information for use in the relationship diagrams, the numbers in the consolidated charts must be converted to whole numbers (Avery 1991). This is done by organizing the ratings for the individual links between work centers / equipment in descending order of importance. Only those links receiving a composite rating of 3.0 or higher are included in the ranking. The inclusion of less important links will clutter the relationship diagram and not provide the designer any additional information. Once the rank order of the importance of the links has been established, they are split into three or four groups based on the breaks in the data. Those links in the highest grouping are assigned an importance rank of four, those in the next highest grouping are assigned an importance rank of three, and so forth until the top four groupings have been assigned importance ranks. Table 1 shows the importance ranking for the work center links from Figure 2. The designer is now ready to prepare the relationship diagrams.

Relationship Diagrams

There are two different types of relationship diagrams: a bubble type and a layout type. The bubble type is done first. This relationship diagram, as shown in Figure 4, uses labeled circles connected by lines to help visualize the important links. The number of lines connecting the different circles corresponds to the importance rank of the links as determined in Table 1. The primary purpose of this type of relationship chart is to help determine which work center(s) should be centrally located, which can be done simply by counting the number of lines connected to the circle. The work center(s) with the greatest number of lines should be centrally located. For simpler drawings, this step can be eliminated, in which case the layout-type relationship chart is drawn directly from Table 1.

Once the work centers that must be centrally located have been determined, the layout-type relationship diagram is drawn. The work centers are drawn to scale inside the space that has been allocated for the operation. The first step in drawing this relationship diagram is to locate any work centers that are anchored to a specific part of the building. For example, the receiving area is generally located along an outside wall, out of public view. Once the centers that must be located in specific parts of the facility are drawn, the designer can begin inserting the remaining work centers, starting with those that must be centrally located. The last centers added to the layout are those centers with few, if any, links to the other work centers. At this point in the design process, the actual shape of each work center is not known. It is up to the designer to estimate the shape of each work center as it is drawn in the diagram. The result is that frequently the area for the last work center is not a functional shape, even though it is the correct size. For example, the remaining area for a 200-ft2 office might be 2 ft wide and 100 ft long, or it could be split into two locations, neither of which would allow the construction of an acceptable office. If this happens, the layout-type relationship chart must be redrawn and the shapes and locations of some of the work centers modified to allow a functional office to be included. This process may need to be repeated several times to ensure that there is enough usable space for all work centers. An example of a completed layout-type relationship diagram is shown in Figure 5.

Designing for Supervision

Designing for ease of supervision as well as efficiency is one of the basic design principles (Birchfield 1988; Kazarian 1989). Relationship diagrams, however, do not take designing for supervision into account. For example, the location of kitchen office is essential for adequate supervision, but the information provided by the workers is not very helpful when it comes to locating the kitchen office. Because the office is not an area that workers visit frequently during production, it is likely to receive low importance ratings for being located near production areas, as can be clearly seen in Figures 1

and 2. Therefore, it is up to the designer to ensure that the kitchen office is properly placed to provide adequate supervision of the kitchen. The placement of the office is further complicated by other functions for which the office is used. Birchfield (1988) describes the need for the office to be accessible to customers needing to talk to management without having those customers walk through the kitchen to reach the office. Further, managers must also monitor the movement of food and supplies in and out of the building and storage areas. This places the office near the receiving area, which would cause problems for customers accessing the office. The final location of the office is often a compromise and depends on which function management views as its primary one.

Designing for Efficient Utility Use

Another important consideration when arranging the kitchen is efficient use of utilities. As with the office, the information provided by the relationship charts and diagrams will not adequately address this issue. Frequently, designing for efficient utility use conflicts with designing for maximum worker efficiency. Kazarian (1989) recommends that heating and cooling equipment be separated. While this is important for controlling energy use, it does not always provide for efficient production. Frequently, food is moved directly from a refrigerator to a piece of cooking equipment. Designing for efficient energy use would place the pieces of equipment some distance apart, while designing for efficient production would place them adjacent to each other. In this case, the designer must weigh the need for energy conservation against the need for worker efficiency and develop an arrangement that minimizes total production costs.

There are several other arrangement considerations that can help reduce energy consumption. One is locating steam- and hot water-generating equipment near the equipment that uses steam or hot water. Shortening the distance between the generation and use of steam or hot water will reduce energy loss from the pipes connecting the equipment. Another way to help reduce energy consumption is to consolidate as many pieces of heat-generating equipment under one exhaust hood as possible. This will reduce costs by reducing ventilation requirements. Finally, Avery (1985) recommends that compressors and condensers for large cooling equipment such as walk-in refrigerators and freezers be located so that the heat they generate can be easily exhausted, thereby reducing the cooling requirements for the kitchen. As with the example in the previous paragraph, arranging the kitchen to take advantage of these energy conservation techniques may conflict with arranging for maximum worker efficiency. It is up to the designer to develop a compromise arrangement that will minimize the total cost of operating the facility.

Evaluating the Efficiency of a Layout

Overview

Kazarian (1989) describes a cross-charting technique that uses distance, move, and travel charts to compare two or more layouts to determine which is the most efficient. This technique recognizes that if the time spent walking between equipment can be reduced, then the worker can spend more time being productive. Avery (1985) took the use of cross-charting one step further. He recognized that not all production workers are paid the same wage. It is possible to have an arrangement that is the most efficient based on total man-hours, but not the most efficient in total labor cost. Because of different training and skill requirements, it is possible for the highest-paid workers to make twice what the lowest-paid workers make. If the travel charts are adjusted for wages, then the comparison of arrangements is based on cost efficiency and not man-hour efficiency.

The first cross-chart that must be prepared is the distance chart. This chart contains the distance from each piece of equipment to all the other pieces of equipment in the work center. Table 2 shows an example of a completed distance chart. The pieces of equipment listed across the top of the chart are the starting points for the movements, and those listed down the side are the ending points. The order of the pieces of equipment in the list depends on the arrangement of the work center. Adjacent pieces of equipment should be listed next to each other in the chart. Listing the equipment in that order will make it easier to recognize ways to rearrange the work center so that it can be more productive. If the chart was prepared properly, then cells adjacent to the diagonal line will contain the smallest numbers and those farther away from the diagonal line will contain larger the numbers.

Move Charts

The move chart is a frequency chart that tracks the number of times a worker moves from one piece of equipment to another. Equipment is listed in these charts in the same order as in the distance chart. There are several ways to determine the frequencies of movement between the different pieces of equipment. The most accurate way is to observe the workers and record their movements. If this is not possible, a reasonable estimate can be developed using the menus and estimating the number of times workers will move between each pair of equipment. If the wages of the different classifi- cations of workers using the facility are significantly different, then multiple move charts should be prepared, one for each classification. Table 3 shows examples of the move charts for two classifi- cations of workers.

Travel Charts

After the distance and move charts are complete, they are used to generate travel charts. The indi- vidual cells in the travel charts are the products of the corresponding cells in the distance and move charts. The cells in the travel charts sum to the total distance traveled by the worker. Once the total distances traveled by each classification of workers are calculated, those numbers are weighted by

their wages. Finally, a single sum is calculated for all the charts. That number can now be used to compare two or more arrangements. The arrangement that yields the smallest number is the most efficient in terms of labor costs. Table 4 show the travel charts for this example. The weighted sum for the prep cook’s chart is 24,850 and the weighted sum of the dishwasher’s chart is 9,240. Com- bining the two, the weighted sum for the operation is 34,090. The units are in currency times distance. The exact units used for currency and distances are not important, as long as they are consistent for each layout being evaluated.

Evaluating the Charts

The final step is to evaluate the charts to identify ways to improve the arrangement of equipment. There are basically two different ways to do this. One is to modify the arrangement, and the other is to modify the production procedures. For an efficient arrangement, the majority of the movement will be between adjacent equipment. Since the distance chart was set up so that adjacent equipment in the arrangement appeared in adjacent cells, the move chart can be used to identify problems with the arrangement. If the work center is properly arranged, the numbers in the cells along the diagonal line should be large and get progressively smaller the farther they are from the line. Rearranging the layout so that the largest numbers are adjacent to the line will improve the efficiency of the operation. In the prep cook’s chart, one possible change in the arrangement that may reduce the total distance traveled is to move the walk-in closer to the sink than the oven is. The total number of moves between the prep table and the walk-in is 65 (45 from the walk-in to the sink and 20 from the sink to the walk-in), while the total number of moves between the walk-in and oven is only 20 (10 from the oven to the sink and 10 from the sink to the oven). Because moving one piece of equipment affects other pieces of equipment, the only way to be sure that the new arrangement is indeed better is to chart the new arrangement and compare the total weighted sums for both arrangements. When there is more than one travel chart because of different wage rates, both charts must be prepared for the new arrangement.

Be careful when making adjustments based on the move chart for the lowest-paid worker. While those adjustments may reduce the total man-hours need to perform the task, they may actually increase the total labor cost for the operation. For example, from the dishwasher’s chart in Table 3, one possible change would be to move the dishwashing machine closer to the prep table. While this would reduce the travel of the lowest-paid worker, it may increase the travel of the highest-paid worker. Therefore, moving the dishwashing machine may increase labor dollars, making this an unwise adjustment to the arrangement.

Identifying procedural changes using these charts is not as straightforward as identifying arrange- ment changes. Basically, these charts can only be used to identify problems with procedures requiring further investigation. In the example in Table 3, there is a total of 100 trips to and from the dishwasher made by the prep cook and another 120 trips made by the dishwasher. The dishwasher’s trips are all between the dishwasher and the prep table. This is an area requiring further investigation to see whether procedural changes are needed. The designer should seek to uncover the reason for the trips. It could be that the prep cook is bringing dirty dishes to the dishwasher and returning empty-handed and that the dishwasher is returning clean dishes to the prep table and returning empty-handed. If

this is the case, then the dishwasher may be able to drop off clean dishes and pick up the dirty dishes. Making this procedural change reduces the total trips between the two areas. Further savings are realized because all the trips are now made by the lowest-paid worker.

Kitchen Ergonomics

Overview

Another method that can be used to help improve the productivity in kitchens is the application of ergonomic principles. Commercial food preparation is a physically demanding occupation. Typically, employees must stand for long periods of time on hard surfaces. As their shifts proceed, workers often become fatigued and experience impaired perception and reduced physical performance, both of which will negatively impact their productivity (Almanza et al. 2000; Avery 1985). The application of sound ergonomic principles can delay the onset of fatigue, making the workers more productive over the course of the day. Something as simple as an incorrect table height can accelerate the onset of fatigue. If a worker is standing vertically, then between 20–27% of his or her energy expenditure can be used to perform work. If that same worker is stooping, then the percent of energy expenditure available to perform work drops to around 5% (Avery 1985). Providing workers the proper table height will allow them to have four to five times more energy to devote to production than they would have if they were stooping.

Table Heights

The correct table height depends on the type of work being performed and who is performing the work. For heavy work, the ideal height is the point where the wrist bends when the arms are hanging at the person’s sides. This puts the table height for heavy work at 76–91 cm (34–36 in.), depending on the person (Almanza et al. 2000; Avery 1985). For lighter work, there seems to be some disa- greement among the industry experts on what is the proper height in terms of body dimension. Katsigris and Thomas (1999) recommend that the surface height be 10 cm (4 in.) below the bend in the elbow. Avery (1985) recommends 2.5–7.6 cm (1 to 3 in.) below the bend in the elbow, and Kazarian (1989) recommends 7.6 cm (3 in.). Despite their differences on where the table should be located in reference to the worker, they all agree that the range is 94–99 cm (37–39 in.) for women and 99–104 cm (39–41 in.) for men.

The new smaller kitchens do not have enough room to have separate tables for different workers and different tasks. One way to overcome this problem and provide the optimum table height is to use adjustable tables. These are available, but their use is not yet widespread.

Heights of Other Equipment

While a significant amount of food preparation takes place at tables, it is also important that other kitchen equipment be at the proper height. Height is of particularly important for sinks, stacked equipment, storage equipment, and top-loading equipment. Most other equipment follows the same rules as tables when it comes to height.

According to Avery (1985), the height of the top of the sink should be 94–99 cm (37–39 in.) for women and 99–102 cm (39–40 in.) for men. The depth of the sink depends on its function. For standard sinks, the bottom of the sink should be at the tip of the worker’s thumb when the arms are at the worker’s sides. This places the bottom at approximately 69 cm (27 in.) for women and 74 cm (29 in.) for men. If the sink is to be used to soak pans, the bottom can be 15 cm (6 in.) lower, provided small items are not placed in the sink.

Avery (1985) also presents information on the importance of height for stacked items such as an oven. He recommends that deck ovens be stacked not more than two high and that the bottom oven be at least 51 cm (20 in.) off the ground. If three ovens are stacked and the first oven is at least 51 cm (20 in.) off the ground, there is a greater risk that workers will be burned trying to use the top oven. If the top oven is at an acceptable height, the bottom oven will be below 51 cm (20 in.), increasing the risk that a worker will be burned using that oven. Further, the worker will have to expend more energy stooping to place things in and remove them from the bottom oven. Stacking of other types of ovens is also not recommended. Conventional and convection ovens are too tall to stack without the risk of serious burns to those using them. It is far safer to put the oven on a stand so the opening is between the workers’ waists and shoulders.

Restaurants often employ several different types of storage devices, from refrigeration and warm- ing cabinets to plate and tray dollies to standard shelves. The proper height for storage of frequently used items is between the worker’s waist and shoulders (Avery 1985). Placing items too high can lead to items being improperly placed on shelves, which can lead to falling objects and the related potential for damage and personal injury. Placing items too low forces workers to stoop, causing them to expend additional energy and putting a strain on their back muscles. In the process of designing small, efficient kitchens, designers have turned to undercounter storage units, such as refrigerators. If the use of undercounter storage units is necessary, the designers should consider using drawers instead of reach-ins because they require less bending and stooping to access products. Finally, if plate and tray dollies are used, they should be self-leveling, meaning that as one plate or tray is removed, the load on the springs at the bottom of the stack decreases, decreasing the com- pression of the spring and raising the stack. This keeps the items within easy reach of the workers.

With top-loading pieces of equipment such as steam-jacketed kettles, pots and pans, and mixers, it is important for the user to be able to reach comfortably and safely over the rim. This helps prevent burns, spills, and similar accidents when workers are adding ingredients or stirring the mixture. Avery (1985) recommends a rim height of no greater than 97 cm (38 in.) for steam-jacketed kettles, when- ever possible. Operations that use large kettles must exceed that height to ensure that the draw-off is high enough to allow a pan to be placed beneath it. The same height recommendations for steam- jacketed kettles also apply to other top-loading equipment, such as stock pots and mixers.

Workstation Dimensions

In addition to proper surface height being maintained, the length and width of the workstations must also be addressed to help workers be productive. For a standing worker, the workstation should be arranged so that the majority of the tasks can be performed in a 46-cm (18-in.) arc centered on the worker (Avery 1985). Supplies needed to perform the tasks can be stored just outside that arc. Since people tend to spread out to fill their environment, it is important that table size be restricted to ensure efficient production. Almanza et al. (2000) recommend limiting the table size for a single work to 61–76 cm (24–30 in.) wide and 1.22–1.83 m (4–6 ft) long. The width of the table can be increased to 91 cm (36 in.) if the back of the table will be used for storage and to 107 cm (42 in.) if two workers will be using opposite sides of the table. If the two workers will be working side by side, then the table length should be 2.44–3.05 m (6–8 ft).

Comments

Post a Comment