DESIGN FOR MANUFACTURING:GENERAL PRINCIPLES FOR DESIGN FOR MANUFACTURABILITY

GENERAL PRINCIPLES FOR DESIGN FOR MANUFACTURABILITY

In this section we only stress some important concepts. In later sections we will review the design for basic processes. For more detailed information, see Bralla (1986) and Stillwell (1989).

1. Consider the entire product, including all its subsystems and components, and the entire spectrum of manufacturing–inspection–assembly activities. We should avoid producing im- provement in one at the expense of another. For example, product design to specify the assembly operations may create difficulties in disassembling the product, thus hurting main- tainability and serviceability of the product. Simplifying the component processing may create complexity in assembly.

2. Search for simplicity first in system designs, then in subsystem designs, and then in com- ponent designs. Considering simplicity in component level only will lead to missing the opportunities for significant improvement.

3. Ask whether the functional needs are absolutely necessary. Chances are the functional needs can be reduced, thus leading to significant simplifications of the configuration design and processing requirements. Example: A careful examination of the functional needs of a gear train system has led to a relaxation of the functional specifications that enables the use of a four-bar linkage as a replacement of the gear train. The impact on manufacturability is ob- viously very significant.

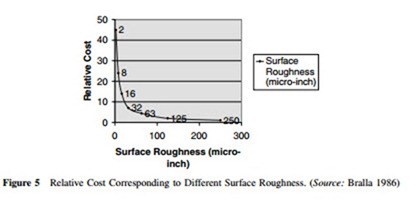

4. Design for fewer parts, simpler shapes, least precision requirements, fewer manufacturing steps, and minimum information requirements. Figure 5 shows the relative cost corresponding to different surface roughness.

5. Apply the concept of design modularization and group technology. Reduce the varieties of sizes and shapes. Experience has shown that the number of hole sizes may be reduced sig- nificantly without affecting the function, thus reducing the number of sizes of drills needed.

6. Always consider standard materials, components, and subassemblies.

7. Design appropriate to the expected level of production and to fit the existing production facilities.

8. Select the shape of the raw material close to the finished designs.

9. Design for easy inspection.

10. Design for part orientation to maximize the value added in each setup.

11. Design for easy assembly and maintainability.

Comments

Post a Comment