PHYSICAL TASKS:DESIGN OF MANUAL MATERIALS HANDLING TASKS

DESIGN OF MANUAL MATERIALS HANDLING TASKS

Epidemiology of Low-Back Disorders

As reviewed by Ayoub et al. (1997), manual materials-handling (MMH) tasks, which include unaided lifting, lowering, carrying, pushing, pulling, and holding activities, are the principal source of com- pensable work injuries affecting primarily the low back in the United States (NIOSH 1981; National Academy of Sciences 1985; Federal Register 1986; Bigos et al. 1986; Battie´ et al. 1990). These include a large number of low-back disorders (LBDs) that are due to either cumulative exposure to manual handling of loads over a long period of time or to isolated incidents of overexertion when handling heavy objects (BNA 1988; National Safety Council 1989; Videman et al. 1990). Overex- ertion injuries in 1985 for the United States accounted for 32.7% of all accidents: lifting objects (15.1%), carrying, holding, etc. (7.8%), and pulling or pushing objects (3.9%). For the period of 1985–1987, back injuries accounted for 22% of all cases and 32% of the compensation costs.

In the United States, about 28.2% of all work injuries involving disability are caused by over- exertion, lifting, throwing, folding, carrying, pushing, or pulling loads that weigh less than 50 lb (National Safety Council 1989). The analysis by industry division showed that the highest percent of such injuries occurred in service industries (31.9%), followed by manufacturing (29.4%), trans- portation and public utility (28.8%), and trade (28.4%). The total time lost due to disabling work injuries was 75 million workdays, while 35 million days were lost due to other accidents. The total work accident cost was $47.1 billion; the average cost per disabling injury was $16,800. Spengler et al. (1986) reported that while low-back injuries comprised only 19% of all injuries incurred by the workers in one of the largest U.S. aircraft companies, they were responsible for 41% of the total injury costs. It is estimated that the economic impact of back injuries in the United States may be as high as 20 billion annually, with compensation costs exceeding $6 billion per year (BNA 1988).

Major components of the MMH system, related risk factors for low-back pain (LBP), and LBDs include worker characteristics, material / container characteristics, task / workplace characteristics, and work practice characteristics (Karwowski et al. 1997). A wide spectrum of work- and individual- related risk factors have been associated with the LBP and LBDs (Riihima¨ki 1991). However, the precise knowledge about the extent to which these factors are etiologic and the extent to which they are symptom precipitating or symptom aggravating is still limited. Kelsey and Golden (1988) reported that the risk of lumbar disk prolapse for workers who lift more than 11.3 kg (25 lb) more than 25 times a day is over three times greater than for workers who lift lower weights. The OSHA (1982) study also revealed very important information regarding workers perception of the weights lifted at the time of injury. Among the items perceived by the workers as factors contributing to their injuries were lifting too-heavy objects (reported by 36% of the workers) and underestimation of weight of objects before lifting (reported by 14% of the workers).

An important review of epidemiological studies on risk factors of LBP using five comprehensive publications on LBP was made by Hildebrant (1987). A total of 24 work-related factors were found that were regarded by at least one of the reviewed sources as risk indicators of LBP. These risk factors include the following categories:

1. General: heavy physical work, work postures in general

2. Static workload: static work postures in general, prolonged sitting, standing or stooping, reach- ing, no variation in work posture

3. Dynamic workload: heavy manual handling, lifting (heavy or frequent, unexpected heavy, infrequent, torque), carrying, forward flexion of trunk, rotation of trunk, pushing / pulling

4. Work environment: vibration, jolt, slipping / falling

5. Work content: monotony, repetitive work, work dissatisfaction

Many of the cross-sectional studies have shown that LBP is related to heavy manual work (Riih- ima¨ki 1991). MMH activities, including those that involve sudden body motions, have been associated with LBP (Svensson and Andersson 1983; Frymoyer et al. 1983, Hansson 1989; Bigos et al. 1991). Among the office workers, LBP was most commonly attributed to lifting tasks (Lloyd et al. 1986). An increased risk of herniated disc was also reported in jobs involving heavy lifting combined with body twisting and forward bending (Kelsey et al. 1984). Manual lifting tasks are often associated with adopting nonneutral trunk postures, which also have been related to LBP (Frymoyer et al. 1980; Maeda et al. 1980; Keyserling et al. 1988; Riihima¨ki et al 1989).

In addition to physical factors, several studies identified a variety of psychological and psycho- social risk factors of LBP that are related to work environment (Damkot et al. 1984; Magora 1973; Svensson and Andersson 1983, 1989; Bigos et al. 1991). However, as pointed out by Riihima¨ki (1991), since most of the studies have been retrospective in nature, it is difficult to determine whether these factors are antecedents or consequences of back pain (Kelsey et al. 1988), and whether these factors play a role in the etiology of LBDs or only affect the perception of symptoms and sickness behavior.

MMH Capacity Design Criteria

Workers who perform heavy physical work are subjected not only to forces and stresses from the immediate physical environment but also to mechanical forces generated from within the body. As a result of these forces and stresses, a strain is produced on the worker’s musculoskeletal system as well as on other systems such as the cardiopulmonary system. One of the most important issues in the application of ergonomics to work design is to reduce the stresses imposed on the musculoskeletal and cardiopulmonary systems (Ayoub and Mital 1989). Several approaches have been used by dif- ferent investigators to establish safe handling limits, including the psychophysical approach, the physiological approach, and the biomechanical approach.

The Psychophysical Approach

The psychophysical approach relies on the worker’s perceived exertion to quantify his or her tolerance level, thereby establishing the maximum acceptable weights or forces (MAW / F) for different MMH activities (e.g., maximum acceptable weight of lift [MAWL]). Psychophysics deals with the relation- ship between human sensation and their physical stimuli. Borg (1962) and Eisler (1962) found that the perception of both muscular effort and force obey the psychophysical function, where sensation magnitude (S) grows as a power function of the stimulus (I ). Stevens (1975) reported the relationship between the strength of the sensation (S) and the intensity of its physical stimulus (I) by the power function:

The use of psychophysics in the study of MMH tasks requires the worker to adjust the weight, force, or frequency in a handling situation until they feel it represents their MAW / F (Asfour et al. 1984; Gamberale and Kilbo¨m 1988; Garg and Banagg 1988; Legg and Myles 1985; Mital et al. 1989; Snook and Ciriello 1991). Psychophysical limits usually refer to weights or forces (MAW / F), although maximum acceptable frequencies have also been established (e.g., Nicholson and Legg 1986; Snook and Ciriello 1991). Despite the relative simplicity of the psychophysical method to determine acceptable limits for manual lifting, which makes this approach quite popular (Karwowski et al 1999), caution should be exercised with respect to interpretation and usability of the currently available design limits and databases.

MMH Design Databases

One can use already available databases such as the one reported by Snook and Ciriello (1991). Another database was reported by Mital (1992) for symmetrical and asymmetrical lifting, and other databases include work by Ayoub et al. (1978) and Mital (1984). Using such available data replaces conducting a study for every work task and group of workers. Tables provided by the various inves- tigators can be used to estimate the MAW / F for a range of job conditions and work populations. The databases provided in tabular format often make allowances for certain task, workplace, and / or worker characteristics. The use of databases begins with the determination of the various character- istics with which the database is stratified.

Psychophysical Models

Another method to estimate MAW / F is regression models based on the psychophysical data. Most of these models predict MAWL. The design data presented here are based upon the database of Snook and Ciriello (1991). Table 15 provides Snook and Ciriello’s (1991) two-handed lifting data for males and females, as modified by Mital et al. (1993). Those values that were modified have been identified. The data in these tables were modified so that a job severity index value of 1.5 is not exceeded, which corresponds to 27.24 kg. Likewise, a spinal compression value that, on average, provides a margin of safety for the back of 30% was used for the biomechanical criterion, yielding a maximum load of 27.24 for males and 20 kg for females. Finally, the physiological criterion of energy expenditure was used. The limits selected were 4 kcal / min for males and 3 kcal / min for females for an 8-hr working day (Mital et al. 1993). The design data for maximal acceptable weights for two-handed pushing / pulling tasks, maximal acceptable weights for carrying tasks, and maximal acceptable holding times can be found in Snook and Ciriello (1991) and Mital et al. (1993). The maximal acceptable weights for manual handling in unusual postures are presented by Smith et al. (1992).

The Physiological Approach

The physiological approach is concerned with the physiological response of the body to MMH tasks. During the performance of work, physiological changes take place within the body. Changes in work methods, performance level, or certain environmental factors are usually reflected in the stress levels of the worker and may be evaluated by physiological methods. The basis of the physiological ap- proach to risk assessment is the comparison of the physiological responses of the body to the stress of performing a task with levels of permissible physiological limits. Many physiological studies of MMH tended to concentrate on whole body indicators of fatigue such as heart rate, energy expen- diture, blood lactate, or oxygen consumption as a result of the workload. Mital et al. (1993) arrived at the same conclusion as Petrofsky and Lind, that is, that the physiological criteria for lifting activities for males should be approximately 4 kcal / min and 3 kcal / min for females.

The energy cost of manual handling activities can be estimated based on the physiological re- sponse of the body to the load, that is, by modeling the physiological cost using work and worker characteristics. The estimates obtained from such models are then compared to the literature rec- ommendations of permissible limits. Garg et al. (1978) report metabolic cost models. Although cur- rently in need of update, they still provide a more comprehensive and flexible set of physiological cost models as a function of the task variables. The basic form of the Garg et al. model is:

Different models require different input data, but typically most of these models involve input information regarding task type, load weight / force, load size, height, frequency, and worker char- acteristics, which include body weight and gender.

The Biomechanical Approach

The biomechanical approach focuses on the establishment of tissue tolerance limits of the body, especially the spine (e.g., compressive and shear force limits tolerated by the lumbar spine). The levels of stresses imposed on the body are compared to permissible levels of biomechanical stresses, measured by, for example, peak joint moments, peak compressive force on the lumbar spine, and peak shear forces on the lumbar spine. Other measures include mechanical energy, average and integrated moments or forces over the lifting, and MMH activity times (Andersson 1985; Gagnon and Smyth 1990; Kumar 1990). Methods used to estimate the permissible level of stress in biome- chanics for MMH include strength testing, lumbar tissue failure, and the epidemiological relationship between biomechanical stress and injury.

Tissue failure studies are based on cadaver tissue strength. Generally, the research has focused on the ultimate compressive strength of the lumbar spine. Studies and literature reviews by Brinck- mann et al. (1989) and Ja¨ger and Luttmann (1991) indicate that the ultimate compressive strength of

cadaver lumbar segments varies from approximately 800 N to approximately 13,000 N. Ja¨ger and Luttman (1991) report a mean failure for compression at 5,700 N for males with a standard deviation of 2600 N. For females, this failure limit was found to be 3900 N with a standard deviation of approximately 1500 N. In addition, several factors influence the compressive strength of the spinal column, including age, gender, specimen cross-section, lumbar level, and structure of the disc or vertebral body. The ultimate compressive strength of various components of the spine can be esti- mated with following regression model (Ja¨ger and Luttman 1991):

It should be noted that statically determined tolerances may overestimate compressive tolerances (Ja¨ger and Luttman 1992b). Modeling studies by Potvin et al. (1991) suggest that erector spinae oblique elements could contribute about 500 N sagittal shear to leave only 200 N sagittal shear for discs and facets to counter. According to Farfan (1983), the facet joints are capable of absorbing 3,100 N to 3,600 N while the discs support less than 900 N.

Due to the complexity of dynamic biomechanical models, assessment of the effects of lifting on the musculoskeletal system has most frequently been done with the aid of static models. Many lifting motions, which are dynamic in nature, appear to have substantial inertia components. McGill and Norman (1985) also compared the low-back moments during lifting when determined dynamically and statically. They found that the dynamic model resulted in peak L4 / L5 moments 19% higher on the average, with a maximum difference of 52%, than those determined from the static model. Given the complexity of the human body and the simplicity of the biomechanical models, values from these models can only be estimates and are best used for comparison purposes rather than suggesting absolute values (Delleman et al. 1992).

Revised NIOSH (1991) Lifting Equation

The 1991 revised lifting equation has been expanded beyond the previous guideline and can be applied to a larger percentage of lifting tasks (Waters et al. 1993). The recommended weight limit (RWL) was designed to protect 90% of the mixed (male / female) industrial working population against LBP. The 1991 equation is based on three main components: standard lifting location, load constant, and risk factor multipliers. The standard lifting location (SLL) serves as the 3D reference point for evaluating the parameters defining the worker’s lifting posture. The SLL for the 1981 Guide was defined as a vertical height of 75 cm and a horizontal distance of 15 cm with respect to the midpoint between the ankles. The horizontal factor for the SLL was increased from 15 cm to 25 cm displacement for the 1991 equation. This was done in view of recent findings that showed 25 cm as the minimum horizontal distance in lifting that did not interfere with the front of the body. This distance was also found to be used most often by workers (Garg and Badger 1986; Garg 1989).

The load constant (LC) refers to a maximum weight value for the SLL. For the revised equation, the load constant was reduced from 40 kg to 23 kg. The reduction in the load constant was driven in part by the need to increase the 1981 horizontal displacement value from a 15-cm to a 25-cm displacement for the 1991 equation (noted above in item 1). Table 16 shows definitions of the relevant terms utilized by the 1991 equation. The RWL is the product of the load constant and six multipliers:

The multipliers (M) are defined in terms of the related risk factors, including the horizontal location (HM), vertical location (VM), vertical travel distance (DM), coupling (CM), frequency of lift (FM), and asymmetry angle (AM). The multipliers for frequency and coupling are defined using relevant tables. In addition to lifting frequency, the work duration and vertical distance factors are used to compute the frequency multiplier (see Table 17). Table 18 shows the coupling multiplier (CM), while Table 19 provides information about the coupling classification.

The horizontal location (H) is measured from the midpoint of the line joining the inner ankle bones to a point projected on the floor directly below the midpoint of the hand grasps (i.e., load center). If significant control is required at the destination (i.e., precision placement), then H should be measured at both the origin and destination of the lift. This procedure is required if there is a need to: (1) regrasp the load near the destination of the lift, (2) momentarily hold the object at the

destination, or (3) position or guide the load at the destination. If the distance is less than 10 in (25 cm), then H should be set to 10 in (25 cm).

The vertical location (V) is defined as the vertical height of the hands above the floor and is measured vertically from the floor to the midpoint between the hand grasps, as defined by the large middle knuckle. The vertical location is limited by the floor surface and the upper limit of vertical reach for lifting (i.e., 70 in or 175 cm).

The vertical travel distance variable (D) is defined as the vertical travel distance of the hands between the origin and destination of the lift. For lifting tasks, D can be computed by subtracting the vertical location (V) at the origin of the lift from the corresponding V at the destination of the

lift. For lowering tasks, D is equal to V at the origin minus V at the destination. The variable (D) is assumed to be at least 10 in (25 cm) and no greater than 70 in (175 cm). If the vertical travel distance is less than 10 in (25 cm), then D should be set to 10 in (25 cm).

The asymmetry angle A is limited to the range of 0° to 135°. If A > 135°, then AM is set equal to zero, which results in a RWL of 0. The asymmetry multiplier (AM) is 1 - (0.0032A). The AM has a maximum value of 1.0 when the load is lifted directly in front of the body and a minimum value of 0.57 at 135° of asymmetry.

The frequency multiplier (FM) is defined by (1) the number of lifts per minute (frequency), (2) the amount of time engaged in the lifting activity (duration), and (3) the vertical height of the lift from the floor. Lifting frequency (F) refers to the average number of lifts made per minute, as measured over a 15-min period. Lifting duration is classified into three categories: short duration,

moderate duration, and long duration. These categories are based on the pattern of continuous work- time and recovery-time (i.e., light work) periods.

A continuous work-time period is defined as a period of uninterrupted work. Recovery time is defined as the duration of light work activity following a period of continuous lifting. Short duration defines lifting tasks that have a work duration of one hour or less, followed by a recovery time equal to 1.2 times the work time. Moderate duration defines lifting tasks that have a duration of more than one hour, but not more than two hours, followed by a recovery period of at least 0.3 times the work time. Long duration defines lifting tasks that have a duration of between two and eight hours, with standard industrial rest allowances (e.g., morning, lunch, and afternoon rest breaks).

The lifting index (LI) provides a relative estimate of the physical stress associated with a manual lifting job and is equal to the load weight divided by the RWL. According to Waters et al. (1994), the RWL and LI can be used to guide ergonomic design in several ways:

1. The individual multipliers can be used to identify specific job-related problems. The general redesign guidelines related to specific multipliers are shown in Table 20.

2. The RWL can be used to guide the redesign of existing manual lifting jobs or to design new manual lifting jobs.

3. The LI can be used to estimate the relative magnitude of physical stress for a task or job. The greater the LI, the smaller the fraction of workers capable of safely sustaining the level of activity.

4. The LI can be used to prioritize ergonomic redesign. A series of suspected hazardous jobs could be rank ordered according to the LI and a control strategy could be developed according to the rank ordering (i.e., jobs with lifting indices about 1.0 or higher would benefit the most from redesign).

The 1991 equation should not be used if any of the following conditions occur: lifting / lowering with one hand; lifting / lowering for over eight hours, lifting / lowering while seated or kneeling; lifting/ lowering in a restricted workspace, lifting / lowering unstable objects; lifting / lowering while carrying, pushing, or pulling; lifting / lowering with wheelbarrows or shovels; lifting / lowering with high-speed motion (faster than about 30 in / sec); lifting / lowering with unreasonable foot / floor coupling (<0.4 coefficient of friction between the sole and the floor); lifting / lowering in an unfavorable environment (i.e., temperature significantly outside 66–79°F (19–26°C) range; relative humidity outside 35–50% range).

Computer Simulation of the Revised NIOSH Lifting Equation (1991)

One way to investigate the practical implications of the 1991 lifting equation for industry is to determine the likely results of the equation when applying a realistic and practical range of values

for the risk factors (Karwowski 1992). This can be done using modern computer simulation tech- niques in order to examine the behavior of the 1991 NIOSH equation under a broad range of con- ditions. Karwowski and Gaddie (1995) simulated the 1991 equation using SLAM II (Pritsker 1986), a simulation language for alternative modeling, as the product of the six independent factor multipliers represented as attributes of an entity flowing through the network. For this purpose, probability distributions for all the relevant risk factors were defined and a digital simulation of the revised equation was performed.

As much as possible, the probability distributions for these factors were chosen to be represen- tative of the real industrial workplace (Ciriello et al. 1990; Brokaw 1992; Karwowski and Brokaw 1992; Marras et al. 1993). Except for the vertical travel distance factor, coupling, and asymmetry multipliers, all factors were defined using either normal or lognormal distributions. For all the factors defined as having lognormal distributions, the procedure was developed to adjust for the required range of real values whenever necessary. The SLAM II computer simulation was run for a total of 100,000 trials, that is, randomly selected scenarios that realistically define the industrial tasks in terms of the 1991 equation. Descriptive statistical data were collected for all the input (lifting) factors, the respective multipliers, and the resulting recommended weight limits. The input factor distributions were examined in order to verify the intended distributions.

The results showed that for all lifting conditions examined, the distribution of recommended weight limit values had a mean of 7.22 kg and a standard deviation of 2.09 kg. In 95% of all cases, the RWL was at or below the value of 10.5 kg (about 23.1 lb). In 99.5% of all cases, the RWL value was at or below 12.5 kg (27.5 lb). That implies that when the LI is set to 1.0 for task design or evaluation purposes, only 0.5% of the (simulated) industrial lifting tasks would have the RWLs greater than 12.5 kg. Taking into account the lifting task duration, in the 99.5% of the simulated cases, the RWL values were equal to or were lower than 13.0 kg (28.6 lb) for up to one hour of lifting task exposure, 12.5 kg (or 27.5 lb) for less than two hours of exposure, and 10.5 kg (23.1 lb) for lifting over an eight-hour shift.

From a practical point of view, these values define simple and straightforward lifting limits, that is, the threshold RWL values (TRWL) that can be used by practitioners for the purpose of immediate and easy-to-perform risk assessment of manual lifting tasks performed in industry. Because the 1991 equation is designed to ensure that the RWL will not exceed the acceptable lifting capability of 99% of male workers and 75% of female workers, this amounts to protecting about 90% of the industrial workers if there is a 50 / 50 split between males and females. The TRWL value of 27.5 lb can then be used for immediate risk assessment of manual lifting tasks performed in industry. If this value is exceeded, then a more thorough examination of the identified tasks, as well as evaluation of physical capacity of the exposed workers, should be performed.

Prevention of LBDs in Industry

The application of ergonomic principles to the design of MMH tasks is one of the most effective approaches to controlling the incidence and severity of LBDs (Ayoub et al. 1997). The goal of ergonomic job design is to reduce the ratio of task demands to worker capability to an acceptable level (see Figure 14). The application of ergonomic principles to task and workplace design perma- nently reduces stresses. Such changes are preferable to altering other aspects of the MMH system, such as work practices. For example, worker training may be ineffective if practices trained are not reinforced and refreshed (Kroemer 1992), whereas altering the workplace is a lasting physical inter- vention

Job Severity Index

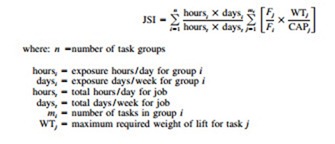

The job severity index (JSI) is a time- and frequency-weighted ratio of worker capacity to job demands. Worker capacity is predicted with the models developed by Ayoub et al. (1978), which use isometric strength and anthropometric data to predict psychophysical lifting capacity. JSI and each of the components are defined below.

Liles et al. (1984) performed a field study to determine the relationship between JSI and the incidence and severity of LBDs. A total of 453 subjects was included in the study. The results of the field study indicated that both incidence and severity of recordable back injuries rose rapidly at values of JSI greater than 1.5. The denominator for the incidence and severity rates is 100 full-time employees, that is, 200,000 exposure hours. JSI can be reduced to a desirable level by increasing worker capacity (e.g., selecting a worker with higher capacity) or altering task and job parameters to reduce JSI to an acceptable level.

7.10.2. Dynamic Model for Prediction of LBDs in Industry

Marras et al. (1993) performed a retrospective study to determine the relationships between workplace factors and trunk motion factors and LBD occurrence. A logistic regression analysis was performed to provide a model used to estimate the probability of high-risk LBD membership. High-risk jobs were defined as jobs having incidence rates of 12 or more injuries per 200,000 hours of exposure. The regressors included in the model were lift rate (lifts / hr), average twisting velocity (deg / sec),

maximum moment (Nm), maximum sagittal flexion (degrees), and maximum lateral velocity (deg / sec). The above model can be used to guide workplace design changes because the probability of high-risk LBD membership can be computed before and after design changes. For example, maximum moment could be reduced by decreasing the load weight or the maximum horizontal distance between the load and the lumbar spine, and the associated decrease in high-risk membership probability can be estimated. The model is considerably different from the models discussed above in that LBD risk is not assumed to be related to individual capacity.

Comments

Post a Comment