METHODS ENGINEERING:GUIDELINES

OVERVIEW

Section 2 starts with some criteria for job design. The emphasis is on health and safety; due to progress in technology, every worker will supervise a number of slaves (machines). Section 2 then gives guidelines for organization of groups of workstations, the workstation itself, musculoskeletal disorders, fatigue, and error reduction.

Section 3 discusses gathering and organizing information. After potential projects are prioritized, the existing situation can be recorded. The big picture (between-operations analysis) or the detailed picture (within-operation analysis) can then be analyzed.

Section 4 discusses how to use the information to design.

GUIDELINES

This section discusses (1) criteria of job design, (2) organization of groups of workstations, (3) individual workstations, (4) musculoskeletal disorders, (5) fatigue, and (6) error reduction.

2.1. Criteria of Job Design

Table 1 gives the six ergonomic criteria for job design:

1. Safety is first.

A job design that endangers the worker’s safety or health is not acceptable. However, life does not have infinite value. Management must take reasonable precautions. Naturally, the definition of ‘‘reasonable’’ is debatable. After designing for safety, design for performance, then worker comfort, and, finally, worker higher wants (social, ego, and self-actualization).

2. Make the machine user-friendly.

Make the machine adjust to the worker, not the worker to the machine. If the system does not function well, redesign the machine or procedure rather than blame the operator.

3. Reduce the percentage excluded by the design.

Maximize the number of people who can use the machine or procedure. As mandated by the Americans with Disabilities Act, gender, age, strength, and other personal attributes should not prevent people from using the design.

4. Design jobs to be cognitive and social.

Physical and procedural jobs now can be done by machines—especially in the developed countries. Over 50% of all jobs in the developed countries are in offices.

5. Emphasize communication.

We communicate with machines through controls; machines communicate to us by displays.

Improved communication among people reduces errors and thus improves productivity.

6. Use machines to extend human performance.

The choice is not whether to assign a task to a person or to a machine; it is which machine to use. Small machines (such as word processors and electric drills) tend to have costs (total of capital, maintenance, and power) of less than $0.25 / hr. Even large machines (such as lathes and automobiles) tend to cost only $1–2 / hr. Labor cost (including fringes) tends to be a minimum of $10 / hr, with $15, $20, or higher quite common. What is your wage rate (including fringes) / per hour?

Consider machines as ‘‘slaves.’’ The real question then becomes how many slaves the human will supervise and how to design the system to use the output of the slaves.

2.2. Organization of Groups of Workstations

This section discusses organization of workstations (the big picture) while Section 3 discusses the workstation itself. Table 2 gives seven guidelines:

1. Use specialization even though it sacrifices versatility.

Specialization is the key to progress. Seek the simplicity of specialization; distrust it thereafter, but first seek it. Use special-purpose equipment, material, labor, and organization.

Special-purpose equipment does only one job but does it very well. For example, at McDonald’s a special-purpose grill cooks the hamburger on both sides simultaneously.

Special-purpose material typically trades off higher material cost vs. greater capability.

Labor specialization improves both quality and quantity. More experience, combined with specialized tools, should yield both higher quality and higher quantity. The challenge is that this specialization gives monotonous work; with low pay, it is difficult to find workers. With high pay, finding employees is not a problem.

From Work Design: Industrial Ergonomics, 5th Ed., by S. Konz and S. Johnson. Copy- right © 2000 by Holcomb Hathaway, Pub., Scottsdale, AZ. Reprinted with permission.

For organization specialization, we have been describing jobs that are rigidly structured, disciplined, machinelike. There is a need for a high volume of a standardized product. If you don’t have the required volumes, use specialization as a goal. Use group technology to get the benefits of mass production from batch production.

2. Consider both nonprogressive and progressive assembly.

Consider an assembly with N = 60 elements with m = 5 people. Should each of the 5 workers do all 60 elements—a complete workstation, job enlargement, nonprogressive assem- bly? Or should each person do N / m elements—a flow line, job simplification, progressive assembly? Table 3 compares nonprogressive vs progressive assembly.

3. Minimize material-handling (MH) cost.

Material handling does not add value, just cost. Reduce this cost by analysis of its components.

• MH cost / yr = capital cost + operating cost

• Operating cost = (no. of trips / yr)(cost / trip)

• Cost / trip = fixed cost / trip + (variable cost / distance) (distance / trip)

Capital costs vary little with utilization. For low volumes, the lowest total cost may be for a system with high operating cost but low capital cost. For high volumes, the high capital-cost system may be best.

Reduce the number of trips by moving less often. Consider replacing transportation with communication (e.g., mail vs. e-mail).

Fixed cost / trip includes information transfer; thus, consider computerization. Much trans- portation (and communication) is distance insensitive. Twice the distance does not cost twice as much. This affects plant layout because closer (or farther) locations make little difference.

Variable cost / distance should consider energy and labor costs. Distance / trip may be irrel- evant, especially if a ‘‘bus system’’ can replace a ‘‘taxi system.’’

4. Decouple tasks.

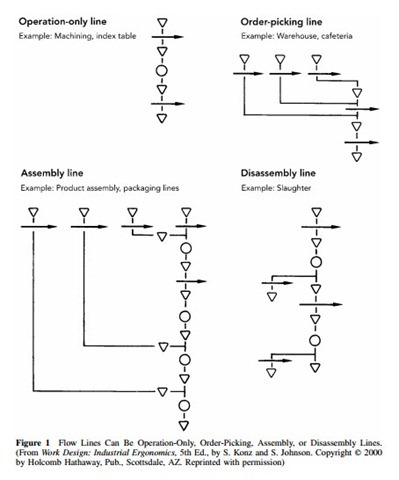

Figure 1 shows different types of flow lines. Table 4 shows some alternatives for conveyor movement, work location, and operator posture.

Assuming progressive assembly, the elements are divided among the line’s stations. In most cases, the mean amount of work time allocated to each workstation is not equal. But since

each workstation has the same cycle time, there is some idle time (cycle time - work time) at each station—this is called balance delay time.

Although it may be obvious, (1) the transport between stations need not be by conveyor (carts are a common alternative, either pushed manually or as automatically guided vehicles);

(2) the transport between stations need not be at a fixed speed or time interval; and, very important, (3) there probably will be storages between the operations and transportations. This storage is known as a buffer; its purpose is to decouple the workstations (isolate stations of the line).

The two primary reasons for buffers are line balancing and shocks and disturbances.

Assume the mean times for stations A, B, C . . . are not equal. Assume A took 50 sec, B took 40 sec, and C took 60 sec. Then, without buffers, the line must be set at the speed of the slowest workstation, C. But, in addition, shocks and disturbances cause variability in the mean times. Thus, without buffers, the cycle time must be set at the slowest time of the slowest station, say 65 sec. Buffers give flexibility to the flow line.

There are two buffering techniques: change product flow and move operators. Changing product flow can be done by buffers at or between the stations, buffers due to carrier design, and buffers off-line. Moving operators can be done by (1) utility operator, (2) helping your neighbor, (3) n operators floating among n workstations, and (4) n operators floating among more than n stations. See Konz and Johnson (2000) for an extensive discussion of the various alternatives.

5. Make several identical items at the same time.

Tasks can be divided into three stages: (1) get ready, (2) do, and (3) put away. Reduce cost / unit by prorating the get-ready and put-away stages over more units.

6. Combine operations and functions.

Consider multifunction materials and equipment rather than single-function materials and equipment. For example, an invoice can be used with a window return envelope to reduce sorting the envelope when it is returned and speed processing of the bill. A farmer can combine fertilizing and plowing.

7. Vary environmental stimulation inversely with task stimulation.

For low-stimulation tasks, (1) add physical movement to the task and (2) add stimulation to the environment. The easiest environmental stimulation solution is to allow operators to talk to each other (see Figure 2). Other alternatives are windows and making the break area attractive. For high-stimulation tasks, such as in offices, reduce stimulation by improving both visual and auditory privacy.

2.3. Individual Workstations

Table 5 gives 14 guidelines for workstation design:

1. Avoid static loads and fixed work postures.

Static (isometric) load (from low variability in postures and movement) is bad for the blood supply / disposal of a specific muscle as well as the total body. We will discuss standing, sitting, head / neck, and hand / arm.

• Standing. The veins store the body’s blood. If the legs don’t move, the blood from the heart tends to go down to the legs and stay there (venous pooling). This causes more work for the heart because, for a constant blood supply, when blood per beat is lower, there are more

beats. Venous pooling causes swelling of the legs, edema, and varicose veins. After standing, walking about 10 steps changes ankle blood pressure to about 48 mm Hg (the same level as for sitting). Thus, standing jobs should be designed to have some leg movements. Con- sider a bar rail (to encourage leg movement while standing) and remote storage of supplies (to encourage walking).

• Sitting. Sitting is discussed in workstation guideline 4.

• Head / neck. The head weighs about 7.3% of body weight. For a 90 kg person, that is 6.6 kg (about the same as a bowling ball). Neck problems occur if the head leans forward or backward on the neck. Forward tilt occurs when the person reduces the distance to an object to improve visibility (inspection, fine assembly, VDT work); consider better lighting. Back- ward tilt may occur for people using bifocals at VDT workstations; consider single-vision glasses (work glasses). If the hands are elevated, head- or workstation-mounted magnifiers permit lowering the hands.

• Hand / arm. When an operator holds a workpiece, this not only causes static load but also reduces productivity (since the person is working with one hand, not two).

Keep the upper arm vertical. Support the arm weight by chair arms or a workstation. Pad sharp edges of workstations. Supporting the arms reduces tremor and thus permits more accurate work with the hands.

2. Reduce musculoskeletal disorders.

See Section 2.4.

3. Set the work height at 50 mm below the elbow.

For manipulative work, the optimum is about 50 mm (2 in.) below the elbow. Output does not decrease more than a couple of percent within a range from 125 mm (5 in.) below to 25 mm (1 in.) above the elbow; beyond this, the penalty is greater. If a downward force is required (polishing, sanding), the optimum is probably with the lower arm at a 45° angle.

The three solution techniques are: (1) change work surface height, (2) adjust elbow height, and (3) adjust work height on the machine.

Work surface heights (such as conveyors) often are easily adjustable. Workstation table heights often can be adjusted—perhaps even with motors.

Adjusting elbow height while sitting involves use of an adjustable-height chair. For stand- ing, consider movable wooden platforms for short operators (for tall operators, remove the platform).

Adjusting work height may be as simple as tilting (45 or 90°) a container box. Use containers with short sides. If the part / assembly is held in a fixture, design the fixture to permit vertical and horizontal adjustment. For example, cars are now assembled in rollover frames; the frames allow the operator to work on the car while it is tilted at various angles.

4. Furnish every employee with an adjustable chair.

A chair is a low-cost tool. Chair cost is entirely a capital cost because operating cost and maintenance costs are zero. Assuming a cost of $200 / chair, a life of 11 years, and a one- shift operation of 1800 hr / yr, the cost / hour is $200 / (11 X 1800) = 1 cent / hr. (Often the real comparison is between a chair without good ergonomics vs. one with ergonomic features, and the incremental cost of the good chair is less than $100—that is, less than 0.5 cent / hr.) The cost of labor (wages plus fringes) varies with the job but will be at least $10 / hr, with

$15 or $20 fairly common. Assuming a cost of $10 / hr, a 0.1% change in productivity (30 sec / shift) equals 1 cent / hr.

Even with an ergonomic chair, many people will have back pain if they sit continuously. The reason is that the disks of the back are nourished by movement of the back—no movement, no nourishment. Thus, encourage seating posture variability by having the person walk occasionally (to answer the phone, discuss things with others, take breaks).

5. Use the feet as well as the hands.

The feet can take some of the load off the hands in simple control tasks such as automobile pedals or on / off switches. For human-generated power, the legs have about three times the power of the arms.

6. Use gravity; don’t oppose it.

Consider the weight of the body and the weight of the work. The weight of arm plus hand is typically about 4.9% of body weight; thus, keep arm motion horizontal or downward.

Gravity also can be a ‘‘fixture’’; consider painting the floor vs. the ceiling; welding below you vs. above you, and so on. Gravity also can be used for transport (chutes, wheel conveyors).

7. Conserve momentum.

Avoid the energy and time penalties of acceleration and deceleration motions. Avoid change of direction in stirring, polishing, grasping, transport, and disposal motions. For example, using the MTM predetermined time system, an 18 in. (450 mm) move to toss aside a part is an M18E and an RL1—a total of 0.63 sec. A precise placement would require an M18B, a P1SE, and an RL1—a total of 0.89 sec, an increase of 42%.

8. Use two-hand motions rather than one-hand motions.

For movement of the hand / arm, two hands are better than one. Using two hands takes more time and effort, but more is produced so cost / unit is lower. When one hand (generally the left) is acting as a clamp, consider it as idle and use a mechanical clamp instead.

9. Use parallel motions for eye control of two-hand motions.

When the two hands are both moving, minimize the distance between the hands rather than making the arm motions symmetrical about the body centerline.

10. Use rowing motions for two-hand motions.

A rowing motion is superior to an alternating motion because there is less movement of the shoulder and torso.

11. Pivot motions about the elbow.

For a specific distance, minimum time is taken by pivoting about the elbow. It takes about

15% more time to reach across the body (it also takes more energy since the upper arm is moved as well as the lower arm).

12. Use the preferred hand.

The preferred hand is 5–10% faster and stronger than the nonpreferred hand. Unfortu-

nately, since it is used more, it is more likely to have cumulative trauma. About 10% of the

population uses the left hand as the preferred hand.

13. Keep arm motions in the normal work area.

Figure 3 shows the area for males; Figure 4 shows the area for females. These are the distances to the end of the thumb with no assistance from movement of the back. Closer is better. Figure 5 shows reach distance above and below the horizontal plane.

14. Let the small woman reach; let the large man fit.

The concept is to permit most of the user population to use the design. Alternative statements are ‘‘Exclude few,’’ ‘‘Include many,’’ and ‘‘Design for the tall; accommodate the small.’’

What percentage should be excluded? The Ford–UAW design guide excludes 5% of women for reach, 5% of men for clearance, and 0% of men and women for safety.

Three alternatives are (1) one size fits all, (2) multiple sizes, and (3) adjustability. Examples of one size fits all are a tall door and a big bed. An example of multiple sizes is clothing. An example of adjustability is an automobile seat.

2.4. Musculoskeletal Disorders

2.4.1. Risk Factors

Safety concerns are for short-term (time frame of seconds) effects of physical agents on the body. An example is cutting of a finger. Toxicology generally deals with long-term (years, decades) effects of chemicals on body organs. An example is exposure to acetone for 10 years, causing damage to the central nervous system. Musculoskeletal disorders concern intermediate-term (months, years) effects of body activity upon the nerves, muscles, joints, and ligaments. An example is back pain due to lifting.

Nerves supply the communication within the body. Muscles control movements of various bones. Ligaments (strong, ropelike fibers) connect bones together.

The three main occupational risk factors are repetition / duration, joint deviation, and force. Vi- bration is also an important risk factor. Nonoccupational risk factors can be from trauma outside work or a nonperfect body. The lack of perfection can be anatomical (weak back muscles or weak arm due to an injury) or physiological (diabetes, insufficient hormones).

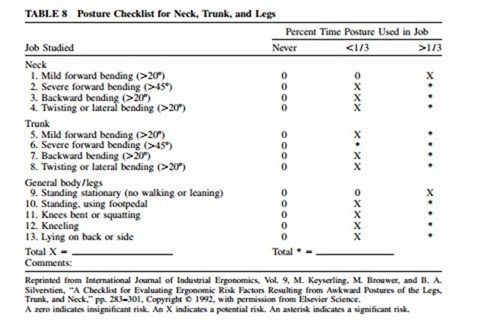

Problem jobs can be identified through (1) records / statistics of the medical / safety department,

(2) operator discomfort (e.g., Figure 6), (3) interviews with operators, and (4) expert opinion (perhaps

using checklists such as Table 6, Table 7, and Table 8).

2.4.2. Solutions

Decrease repetition / duration, joint deviation, force, and vibration.

In general, a job is considered repetitive if the basic (fundamental) cycle time is less than 30 sec

(for hand / wrist motions) and several minutes (for back / shoulder motions). However, if the job is

only done for a short time (say, 15 min / shift), there is relatively low risk of cumulative trauma due

to the short duration. Consider short duration as <1 hr / shift, moderate as 1 to 2 hr, and long as >2

hr. Thus, repetition really concerns the repetitions / shift. Duration also assumes weeks, months, and

years of repeated activity, not just a couple of days.

Ideally the joint should operate at the neutral position—that is, minimum joint deviation.

Force on a joint typically is multiplied by a lever arm (i.e., we are really talking about a torque).

Reduce (1) the magnitude of the force, (2) the lever arm, and (3) the length of time the force is applied.

Vibration typically comes from a powered handtool. Vibration increases force because operators tend to grip the vibrating tool more tightly because it vibrates.

Solutions are divided into engineering and administrative.

2.4.2.1. Engineering Solutions The first possible approach is automation—that is, eliminate the person. No person means no possible injury.

A second possible approach is to reduce the number of cycles or the difficulty of the cycle. Two alternatives are mechanization and job enlargement. In mechanization, the operator is still present but a machine does part of the work. Two examples are electric scissors (vs. manual scissors) and a bar code scanner (instead of information being keyed). In job enlargement, the same motions are done, but by a larger number of people. If the job takes four minutes instead of two, the repetitive motions per person per day are reduced.

The third approach is to minimize joint deviation. One guide is Don’t bend your wrist. For example, place keyboards low to minimize backward bending of the hand. Another guide is Don’t lift your elbow. An example was spraypainting the side of a truck by workers standing on the floor. The job was modified to have the workers stand on a platform, thus painting horizontally and down- ward. (This had the additional benefit of less paint settling back into the painters’ faces.)

The fourth approach is to minimize force duration and amount. Consider an ergonomic pen (large grip diameter with a high-friction grip) to reduce gripping force. Can a clamp eliminate holding by a hand? Can a balancer support the tool weight? Can sliding replace lifting?

To reduce vibration, use tools that vibrate less; avoid amplified vibration (resonance). Maintain the equipment to reduce its vibration. Minimize gripping force (e.g., support the tool with a balancer or a steady rest). Keep the hands warm and dry; avoid smoking.

2.4.2.2. Administrative Solutions Administrative solutions (such as job rotation and part-time workers) seek to reduce exposure or increase operator’s ability to endure stress (exercise, stress reduction, and supports).

In job rotation, people rotate jobs periodically during the shift. The concept is working rest—a specific part of the body rests while another part is working. Job rotation requires cross-trained workers (able to do more than one job), which allows more flexible scheduling; there is perceived fairness because everyone shares good and bad jobs.

Part-time workers reduce musculoskeletal disorders / person. Some other advantages are lower wage cost / hr, better fit to fluctuating demand, and (possibly) higher-quality people. (It is difficult to hire high-quality full-time people for repetitive low-paying jobs.) Some disadvantages are less time on the job (and thus less experience), possible moonlighting with other employers, and a high cost of hiring and training.

Exercises should be tailored to the specific set of muscles, tendons, and ligaments that are stressed. If the work loads the muscles statically, the exercise should move them. If the work loads the muscles dynamically, the exercise should relax and stretch them.

Stress can be caused by social factors, both on and off the job. Supports for the body (armrests, back belts, wrist splints, etc.) are an appealing concept, but evidence is lacking concerning their benefits.

2.5. Fatigue

2.5.1. Background

The problem is to reduce fatigue so workers can maintain / increase productivity and have optimal stress. Fatigue can be divided into five factors:

1. Physical exertion (e.g., bicycle ergonometer work; descriptions such as ‘‘warm,’’ ‘‘sweaty,’’ ‘‘out of breath,’’ ‘‘breathing heavily,’’ ‘‘palpitations’’)

2. Physical discomfort (e.g., static load on small-muscle groups; descriptions such as ‘‘tense muscles,’’ ‘‘aching,’’ ‘‘numbness,’’ ‘‘hurting,’’ ‘‘stiff joints’’)

3. Lack of energy (mental plus physical; descriptions such as ‘‘exhausted,’’ ‘‘spent,’’ ‘‘over- worked,’’ ‘‘worn out,’’ ‘‘drained’’)

4. Lack of motivation (mental; descriptions such as ‘‘lack of initiative,’’ ‘‘listless,’’ ‘‘passive,’’ ‘‘indifferent,’’ ‘‘uninterested’’)

5. Sleepiness (mental; descriptions such as ‘‘sleepy,’’ ‘‘yawning,’’ ‘‘drowsy,’’ ‘‘falling asleep,’’ ‘‘lazy’’).

Jobs will have different combinations of fatigue and the combinations often will vary during the shift. Fatigue generally is overcome by rest (recovery). Rest time can be classified as off-work (evenings, holidays, weekends, vacations) and at-work. At-work is further divided into formal breaks (lunch, coffee), informal breaks (work interruptions, training), microbreaks (short pauses of a minute or less), and working rest (a different task using a different part of the body, such as answering the phone instead of keying data). From the viewpoint of financial cost, some rest time is paid and some is unpaid; from a fatigue viewpoint, a rest is a rest.

In general, weekly, annual, and lifetime working hours are decreasing and thus present fewer health / productivity problems. But daily hours may be a problem, especially for people working more than 8 hr / day and without proper sleep.

2.5.2. Fatigue Guidelines

Table 9 gives seven guidelines concerning fatigue. Guidelines 1, 2, and 3 concern fatigue prevention; guidelines 4, 5, 6, and 7 concern fatigue reduction.

![clip_image035[2] clip_image035[2]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEgVuqD3FttE1FYvRGGQc_vg_uPMorlPGlCLsDBUfNJr61Q2MYpGkpBxMjvdk6kg6FzTpxWIce8h_MvOjxPiO4l07RFPJnS2BD8GuAD8tJBWzVq-C1W2d2V0C6E72L6ijw982nd2lHR1Bv7V/?imgmax=800) TABLE 10 Tips for Day Sleeping

TABLE 10 Tips for Day Sleeping

• Develop a good sleeping environment (dark, quiet, cool, bed). Have it dark (e.g., use eyeshades or opaque curtains). Have it quiet since it is difficult to go back to sleep when daytime sleep is interrupted. Minimize noise volume. Consider earplugs, unplugging bedroom phones, turning down phone volume in other rooms, reducing TV volume in other rooms, Train your children. Have a cool sleeping area. The bed normally is OK but may be poor if the sleeper is not sleeping at home (e.g., is part of an ‘‘augmented crew’’ for trucks, aircraft). Then provide a good mattress and enough space.

• Plan your sleeping time. Tell others your schedule to minimize interruptions. Morning-to-noon bedtimes are the most unsuitable times to sleep. Consider sleeping in two periods (5–6 hr during the day and 1–2 hr in the late evening before returning to work). Less daytime sleep and some late evening sleep not only make it easier to sleep but also may give a better fit with family / social activities.

• Have a light (not zero or heavy) meal before sleep. Avoid foods that upset your stomach and thus wake you up. Avoid liquid consumption, as it increases the need to urinate (which wakes you up). Avoid caffeine. A warm drink before your bedtime (perhaps with family members starting their day) may help your social needs.

• If under emotional stress, relax before going to bed. One possibility is light exercise.

From Work Design: Industrial Ergonomics, 5th Ed., by S. Konz and S. Johnson. Copyright © 2000 by Holcomb Hathaway, Pub., Scottsdale, AZ. Reprinted with permission.

1. Have a work scheduling policy.

The problem is insufficient rest. Two aspects are (1) too many work hours, and (2) work hours at the wrong time.

Too many hours can accrue through by not counting all the hours in duty time. For example, train and flight crews have waiting and preparation time before and after the primary job. Long hours may be from overtime due to absenteeism of another person and / or moonlighting. There probably should be some organizational restriction on prolonged overtime (say over 12 hr / day and over 55 hr / week).

Lack of sleep can result from conflicts with the circadian rhythm. Table 10 gives sleeping

tips; Table 11 gives shiftwork recommendations.

2. Optimize stimulation during work.

Too much stimulation causes overload; too little causes boredom. Stimulation comes from

the task and the environment.

For too much stimulation, reduce environmental stimulation (see Figure 2). For example,

for office tasks, increase visual and auditory privacy.

For too little stimulation, increase either task or environmental stimulation or both. Increase

task stimulation by adding physical work to sedentary jobs or by job rotation. Increase envi-

ronmental stimulation by (1) conversation with others, (2) varying the auditory environment

• Avoid permanent night work. Full entrainment of physiological functions to night work is difficult. Permanent night workers have problems due to readapting to day cycles during weekends, holidays, and vacations.

• If shifts rotate, rapid rotation is preferable to slow (weekly) rotation. Shifts should rotate forward (day, evening, night).

• Avoid starting the morning shift before 7 a.m.

• Consider distribution of leisure time. Have sufficient time to sleep between shifts (e.g., between

shift changeovers). Limit the number of consecutive working days to 5–7. For every shift

system, have some nonworking weekends with at least 2 successive full days off.

• Shift durations of 12 hr have disadvantages as well as advantages. Disadvantages include

fatigue, covering absentees, overtime, limiting toxic exposure, and possible moonlighting when

workers have large blocks of leisure time.

• Make the schedule simple and predictable. People want to be able to plan their personal lives.

Make work schedules predictable. Publicly post them in advance so people can plan; 30 days in

Source: Konz and Johnson 2000, from Knauth, 1993.

(e.g., talk radio), (3) varying the visual environment (e.g., windows with a view), and (4) varying the climate (change air temperature, velocity).

3. Minimize the fatigue dose.

The problem is that the fatigue dose becomes too great to overcome easily. Two aspects

are intensity and work schedule.

Reduce high intensity levels with good ergonomic practices; for example, use machines

and devices to reduce hold and carry activities. Static work (holding) is especially stressful.

The effect of fatigue increases exponentially with time. Thus, it is important to get a rest

before the fatigue becomes too high. Do not permit workers to skip their scheduled break. For

very high-intensity work (e.g., sorting express packages), use part-time workers.

4. Use work breaks.

The problem with a conventional break is that there is no productivity during the break. A

solution is to use a different part of the body to work while resting the fatigued part. If a

machine is semiautomatic, the worker may be able to rest during the automatic part of the

cycle (machine time). Another alternative is job rotation (worker periodically shifts tasks).

Fatigue recovery is best if the alternative work uses a distinctly different part of the body—

for example, loading / unloading a truck vs. driving it, word processing vs. answering a tele- phone.

Not quite as good, but still beneficial, is alternating similar work, as there would be differences in body posture, force requirements, mental activity, because for example, an assembly team might rotate jobs every 30 minutes. In a warehouse, for half a shift, workers might pick cases from a pallet to a conveyor, and during the second half, they would switch with the people unloading the conveyor to trucks. Job rotation also reduces the feeling of inequity because everyone shares the good and bad jobs. However, it does require cross-trained people (able to do multiple jobs). However, this in turn increases scheduling flexibility.

5. Use frequent short breaks.

The problem is how to divide break time. The key to the solution is that fatigue recovery is exponential. If recovery is complete in 30 minutes, it takes only 2 minutes to drop from 100% fatigue to 75% fatigue; it takes 21 minutes to drop from 25% fatigue to no fatigue.

Thus, give break time in small segments. Some production is lost for each break. Reduce this loss by not turning the machine off and on, taking the break near the machine, and so on.

6. Maximize the recovery rate.

The problem is recovering as quickly as possible. In technical terms, reduce the fatigue half-life.

For environmental stressors, reduce contact with the stressor. Use a cool recovery area to recover from heat, a quiet area to recover from noise, no vibration to recover from vibration.

For muscle stressors, it helps to have a good circulation system (to be in good shape). Active rest seems better than passive rest. The active rest may be just walking to the coffee area (blood circulation in the legs improves dramatically within <20 steps). Another technique to get active rest is to have the operator do the material handling for the workstation (obtain supplies, dispose of finished components).

7. Increase the recovery / work ratio.

The problem is insufficient time to recover. The solution is to increase recovery time or decrease work time. For example, if a specific joint is used 8 hr / day, there are 16 hr to recover;

2 hr of recovery / 1 hr of work. If the work of the two arms is alternated so that one arm is used 4 hr / day, there are 20 hr to recover; 5 hr of recovery / 1 hr of work. Overtime, moonlighting or 12 hr shifts can cause problems. Working 12 hr / day gives 12 hr of recovery, so there is 1 hr of recovery / 1 hr of work.

2.6 Error-Reduction Guidelines

Harry and Schroeder (2000) describe the importance from a business viewpoint of joining the ‘‘cult of perfectability.’’ Table 12 gives l0 general guidelines to reduce errors. They are organized into three categories: planning, execution, and allowing for error.

1. Get enough information.

Generating enough information calls for (1) generating / collecting the relevant information and (2) ensuring that the user receives the information.

Generating the information can be aided by computerization. But the information in the computer needs to be correct! Warnings (e.g., auditory alarm when truck backs up) can generate information; unfortunately, not all warnings are followed.

Ensure information reception. Just because you put a message in a person’s mailbox

(voicemail, e-mail), doesn’t mean the person accesses it! Do you know how to use all the buttons on your telephone?

2. Ensure that information is understood.

Although there is much information available on good ergonomic design of displays (in struments as well as print such as text, figures, and tables), unfortunately, not all designers seem to have paid attention to them. Communication with the general public is especially difficult due to their lack of training on your specific system as well as their diverse ages, vision, language abilities, and so on. Equipment and procedures for the general public need to have usability tests using diverse customers.

When transmitting information to others, a good technique is to have them repeat the information back to you in their words. Technically this information feedback has two steps:

forward (you to them) and backward (them to you). As the number of communication nodes increases, the need for feedback increases. Critical messages thus should be written and require confirmation from the user, not only of the receipt of the message but also of the user’s understanding of its message.

3. Have proper equipment / procedures / skill.

Four aspects of equipment are design, amount, arrangement, and maintenance.

With proper equipment design, the potential error is eliminated and procedures and skill are not necessary. Don’t forget foreseeable use and misuse. Some examples are a ground-fault circuit interrupter to eliminate electrocution; a surge protector for computers; design of connectors so they cannot fit into the wrong plug. Equipment guards not only must be installed, they also must remain installed (and not removed by the operator). In some cases, ‘‘antiergonomics’’ is desirable—making something difficult to use. Lockout / tagout prevents equipment from being activated while it is being maintained.

Equipment amount basically involves duplication. Some examples are duplication of computer files, equipment (four engines on an airplane), and even labor (copilot).

Equipment arrangement involves the concepts of series and parallel systems as well as standby systems. Redundancy can just be duplication of the procedure, but it also can be having some information confirm the remainder—an error-checking code. For example, giving a meeting date as Thursday, February 25, lets the Thursday confirm the 25. A ZIP code confirms the names of city and state on a postal address.

Equipment maintenance typically is assumed as a given. However the Union Carbide incident at Bhopal, India, where over 2500 people were killed, demonstrates what can happen when there is an insufficient maintenance budget, for both spare parts and for labor.

Procedures describe the sequence of body motions necessary to accomplish a task. Skill is the eye / brain / hand coordination to perform the body motion.

Develop standard procedures (protocols). Then users need to be trained on the protocol.

The mind seeks patterns and rules and will follow them if they are apparent. Training may require a formal procedure of (1) writing down the training procedure and training aids, (2) designating specific people as trainers, and (3) documenting that a specific person has been trained by a specific trainer on a specific date.

Skill has both mental and physical aspects. Skill or knowledge can be memorized, but an alternative is a job aid (such as information stored in a computer). Practice is important because rookies make more mistakes than old pros; that’s why sports teams practice so much.

4. Don’t forget.

Two approaches to avoid forgetting are to reduce the need to remember and to use memory aids.

Avoid verbal orders: they leave no reference to refresh the memory. If you receive a verbal order, write it down to create a database for future reference.

A list is a popular memory aid; the many electronic organizers being sold attest to the need for making a list. Memory aids include more than that, however. Forms not only include information but also indicate what information is needed. Patterns aid memory. For example, it is easier to remember a meeting is on the first Friday of each month than to remember the 12 individual days. At McDonald’s, orders are filled in a standard sequence; next time you are there, see if you can determine the standard sequence. Other memory aids include the fuel gauge and warning lights in cars and the sticker on the windshield showing when the oil was changed.

5. Simplify the task.

Two ways to simplify tasks are to reduce the number of steps and to improve communication.

Familiar examples of reducing steps are autodialers on telephones and use of address lists for email. Many retailers now have their computers communicate point-of-sale information not only to their own central computer but also to their vendors’ computers. The original concept was to speed vendors’ manufacturing and shipping, but the retailers soon realized that the elimination of all the purchasing paperwork led to drastic error reductions.

Improve communication by improving controls (how people communicate to machines) and displays (how machines communicate to people); details are covered in a number of ergonomics texts. But even letters and numbers can be confused—especially the number 0 and the letter O and the number 1 and the letter l. Use all letter codes or all numeric codes, not a mixture. If a mixed code is used, omit 0, O, 1 and l. Also, do not use both a dash and an underline.

Guidelines 6 and 7 concern execution of tasks.

6. Allow enough time.

Under time stress, people make errors. Start earlier so there is more margin between the start time and the due time. Another technique to reduce time / person by putting more people on the task; this flexibility requires cross-trained people.

7. Have sufficient motivation / attention.

Motivation is not a replacement for engineering. Gamblers are motivated to win, but wanting to win is not enough. Motivation can be positive (aid performance) or negative (hinder performance).

There are many examples of superiors challenging subordinate’s decisions but relatively few of subordinates challenging superior’s decisions. It is difficult, though important, to require important decisions to be challenged by or justified to subordinates. Company policies and culture and openness to criticism are important factors. Even requiring superiors to explain decisions to subordinates can be valuable: when superiors try to explain the decision, they may realize it is a bad decision.

Lack of attention can occur from simple things such as distractions, but it can also be caused by people sleeping on the job or being drunk or ill. One solution technique is to have observation by other people (either personally or by TV) so sleeping, heart attacks, and so on can be observed.

Guidelines 8, 9, and 10 discuss allowing for errors.

8. Give immediate feedback on errors.

Two subdivisions of feedback are error detection and reducing delay.

Errors can be detected by people (inspection) or by machines. Machines can passively display the error (needle in the red zone) or actively display the error (audio warning, flashing light) or even make an active correction (turn on furnace when temperature in the room drops). The machine also can fail to respond (computer doesn’t work when the wrong com- mand is entered). Machines also can present possible errors for human analysis (spell-check programs). Error messages should be specific and understandable. The message ‘‘Error’’ flash- ing on the screen is not as useful as ‘‘Invalid input—value too high. Permissible range is 18 to 65 years.’’ Error messages should not be too irritating or people will turn them off.

Reduce the time (latency) until the error is detected. The more quickly the error is de- tected, the easier it is to detect why the error occurred. A quick correction may also reduce

possible damage. For example, your car may make a noise if you remove the key while the headlights are on; thus, you can turn the lights off before the battery dies.

9. Improve error detectability.

Consider the error as a signal and the background as noise. Improve detectability by having a high signal / noise ratio—a good contrast. Amplify the signal or reduce the noise.

One way to enhance a signal is to match it. For example, if someone gives you a message, repeat it back so he or she can see that you understand the message. A signal also can be increased. For example, putting a switch on can also trigger an indicator light. The signal should not conflict with population stereotypes (expected relationships) and thus be camouflaged. For example, don’t put regular coffee in a decaf container; don’t put chemicals in a refrigerator that also contains food.

Reduce the noise by improving the background. Traffic lights are made more visible by surrounding the lights with a black background. When talking on the phone, turn down the radio.

10. Minimize consequences of errors.

Design equipment and procedures so they are less sensitive to errors—so they are failsafe. A well-designed system anticipates possible problems. What if an instrument light fails?

the address on a letter is incorrect? the pilot has a heart attack? the air conditioning system fails? the paint drips from the brush? Some solutions are redundant instrument lights, return addresses on letters, copilots, windows that open, painting while using a dropcloth. The consequences of many errors can be reduced by guards (e.g., guards to prevent hands touching moving pulley and belts, gloves to prevent chemical burns, hard hats to prevent head injuries).

Ease of recovery also is important. What can be done if a box jams on a conveyor turn?

if a paycheck is lost? if a mistake is made on a computer input? if a car tire has a blowout?

Longer time available for recovery helps. For example, a fire door with a 1 hr rating is better than one with a 0.1 hr rating.

Comments

Post a Comment