PLANNING AND INTEGRATION OF PRODUCT DEVELOPMENT:CHARACTERISTICS OF RAPID PRODUCT DEVELOPMENT

2. CHARACTERISTICS OF RAPID PRODUCT DEVELOPMENT

The Life Cycle

Simultaneous engineering (SE) considers the complete development process and thus carries out the planning on the whole. RPD, on the other hand, considers single tasks and the respective expert team responsible for each task. SE sets up the framework within which RPD organizes the rapid, result- oriented performance of functional activities. The mere application of SE organization on the func- tional level leads to a disproportionate coordination expenditure.

The overall RPD approach is based on the idea of an evolutionary design cycle (Bullinger et al. 1996). In contrast to traditional approaches with defined design phases and respective documents, such as specification lists or concept matrices, the different design phases are result oriented.

The whole cycle is subject to constraints from the project environment, such as market devel- opments, legislation, and new technologies. Late changes in customer requirements (Thomke and Reinertsen 1998) make necessary research and development (R&D) management that is able to handle these uncertainties efficiently. Furthermore, the execution of the cycle is not necessarily sequential. For example, results from the generation of prototypes can be directly incorporated into a new design phase.

The idea of evolutionary design means that previously unrecognized product requirements or technological progress be considered and incorporated. This issue leads to an important feature of RPD, namely, the abandonment of a homogeneus definition of a product throughout the project. Each product module has an individual definition. The initial concept is conceptualized for the complete product as well as the final integration of the modules. In between, changes are made through new design methods and tools.

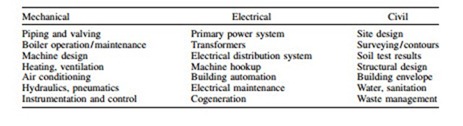

The RPD approach will become more transparent by comparing it to the concept of SE (Bullinger and Warschat 1996). The influencable and controllable parameters of a company will serve as a frame for the comparison (see Table 1):

• Organization

• Processes

• Human and technical resources

• Product

The Organization

Organizational changes, rearrangement of processes, investment in new machines, and training of staff, as well as new solutions for product structures, are necessary to increase the effectiveness and efficiency of the product-development process.

The organization of a company defines its structures, such as the formation of organizational units and the coordination between the units. Project management, as a method that uses certain tools, influences organizational change to a large extent. Whereas SE exhibits a more or less formalized frame with milestones, RPD requires a reactive project-management methodology. The apparent plan precision within phase-oriented approaches such as SE becomes increasingly inaccurate with pro- ceeding project progress. Hence, it will be replaced by a result-oriented approach, where the plan inaccuracy decreases with the progress of the project. For both development approaches, integration of tasks is needed, with labor being planned, controlled, and steered by one responsible person or team.

In the early phases of product development, those decisions are made that are relevant for the creation of value. The organization needs to be flexible enough to provide appropriate competencies for decisions and responsibilities.

The Process

RPD concentrates on the early phases of product development. SE already achieved the reduction of production times. RPD now aims to increase the variety of prototypes through an evolutionary iter- ative process in order to enable comprehensive statements to be made about the product. The inter- disciplinary teams work together from the start. The key factors here are good communication and coordination of everyone involved in the process. Thus, the time for finding a solution to the following problems is reduced:

• There are no customer demands. Therefore, without any concrete forms many solutions are possible, but not the solution that is sought.

• The potential of new or alternative technologies results from the integration of experts, whose knowledge can influence the whole process.

• The changing basic conditions of the development in the course of the process make changes necessary in already finished task areas (e.g. risk estimation of market and technology).

These possible basic conditions have to be integrated into the RPD process to reduce time and costs of the whole process.

The application of processes determines the product development and its effectiveness and effi- ciency. Product data generation and management process can be distinguished. Hence, it is important for the SE as well as the RPD approach to achieve a process orientation in which both product data generation and management process are aligned along the value chain. In a traditional SE approach, innovation results from an initial product concept and product specification, whereas the RPD concept will be checked and redefined according to the project progress. RPD therefore makes it possible to integrate new technologies, market trends, and other factors for a much longer period. Thus, it leads to highly innovative products. Design iterations are a desirable and therefore promoted element of RPD. The change of design concepts and specifications is supported by a fitting framework, including the testing and the most-important evaluation of the design for further improvement.

The Human and Technical Resources

Common SE approaches are based on standardized and static product data integration, whereas RPD requires dynamic data management in semantic networks in order to enable short control cycles. Short paths and multidisciplinary teams for quick decisions are essential for both approaches. More- over, RPD requires team-oriented communication systems, which open up new ways of cooperation. They need to offer support not only for management decisions, but also for decision making during the generation of product data.

In RPD, the people and machines involved are of great importance. The people involved need free space for the development within the framework of the evolutionary concept, and well as the will to use the possibilities for cooperation with other colleagues. This means a break with the Taylorized development process. The employees need to be aware that they are taking part in a continually changing process. The technical resources, especially machines with hardware and soft- ware for the production of digital and physical prototypes, have to meet requirements on the usability of data with unclear features regarding parameters. They have to be able to build first prototypes without detailed construction data. The quality of the statements that can be made by means of the prototypes depends on how concrete or detailed they are. For optimal cooperation of the single technologies, it is important to use data that can be read by all of them.

The Product

The results of the product-development process are the documents of the generated product, such as product models, calculations, certificates, plans, and bills of materials as well as the respective doc- uments of the process, such as drawings of machine tools, process plans, and work plans. The aim of all documentation is to support information management. A documentation focusing on product and process data guarantees project transparency for all the persons involved. The standardization of the whole product data is a basic prerequisite for evolutionary and phase-oriented approaches. STEP (standard for the exchange of product model data), as probably the most promising attempt to stan- dardize product data and application interfaces, offers applicable solutions for quite a few application fields, such as automotive and electronic design, rapid prototyping, and ship building. Documents reflecting parts of the complete product data generated, such as specifications, bills of materials, and process data, represent an important difference between SE and RPD. Whereas in an SE documents are synchronized at a certain time (e.g., milestones), the RPD process documents are subject to persistent alteration until a certain deadline. Thus, figures can be changed or agreed upon and bound- aries narrowed. The RPD approach only sets rough boundaries within which the modules mature individually. This yields in specific project-management questions, such as (re)allocation of resources or synchronization of the overall process, which are presently still subject to research (Malone and Crowston 1994). Therefore, the RPD process focusses specifically on the management of variants and versions.

Comments

Post a Comment